Best Price for Epoxy Injection Molding - Office Chair Back – Uni-Moulding

Best Price for Epoxy Injection Molding - Office Chair Back – Uni-Moulding Detail:

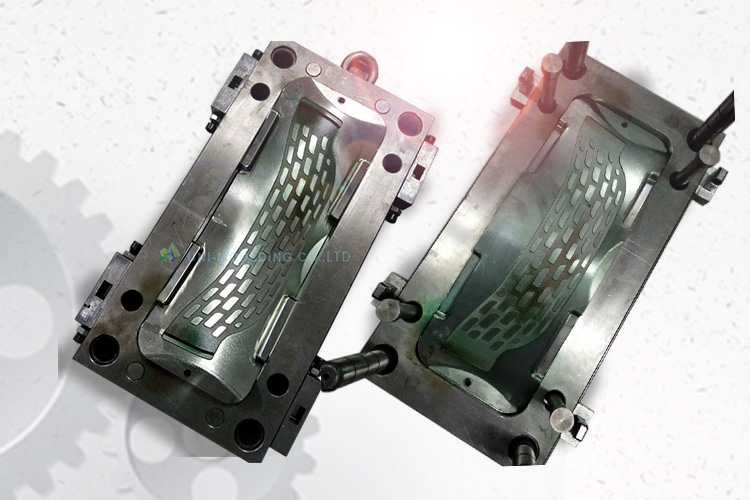

Office Chair Back

Export Country:

England

Completion Time:

1 Month

Tag: Office Chair Back

Challange

The part line is curved, not straight and not ejection pins applied .

Solutions

It highly depends on the mold maker’s skill and knowledge. We are lucky to have our own mold makers who fulfills the job over 20 years.

Product Application Field

Office chair,Office Supplies

Main Challenges

PVC corrosion mold: S136 heat treatment is adopted to increase the hardness and corrosion resistance of the die;

PP chair keel shrinkage: Due to the thick wall thickness of chair keel, PP material is easy to shrink, we first thinned the wall thickness of the keel, and then we added keel ribs to increase the strength of the product. In fact, we add a certain proportion of glass fiber to PP material to increase the strength effect, and appropriately add a certain amount of calcium sulfate and toughening agent to ensure that the product is not easy to shrink and the fluidity of the material can maintain the original properties.

Chair assembly coordination: Before developing the mold, we first processed some samples with a 3D printer, assembled and adapted them, and found out the corresponding problem points, so as to change the design scheme. Before the mold design, we also conducted mold flow analysis on the product, and have used SolidWorks to test the assembly and adaptation details of the product.

The customer designed to use ABS at the wear position of the Department. After test, discussion and negotiation with the customer, the ABS material was replaced with POM material, so that the product has better wear resistance and ensures the service life of plastic office chairs. It has been recognized by customers.

Material replacement:

Main Technology

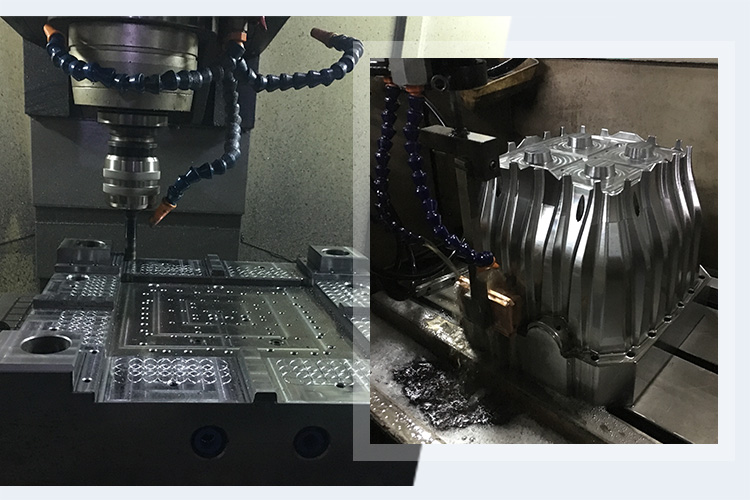

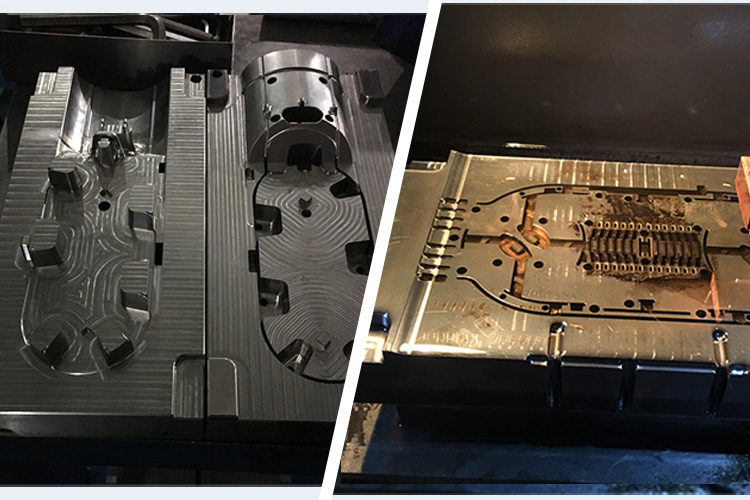

Mold Analysis, CNC Rough Machining, Heat Treating, Finishing Machining, Wire Cutting, EDM, Polishing, Texture.

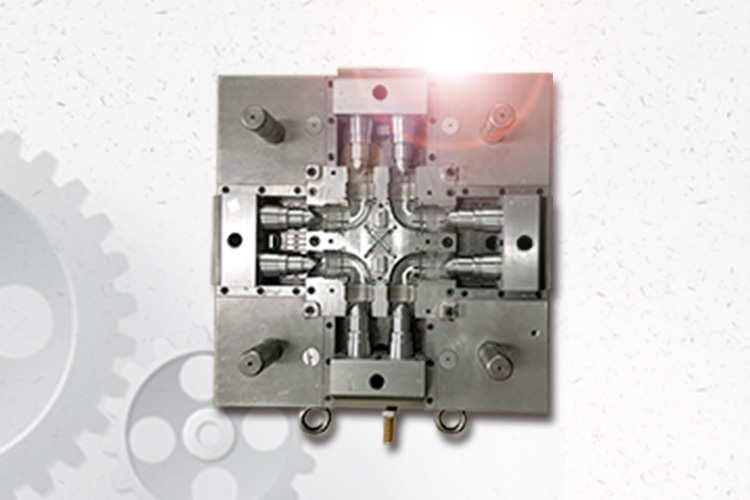

Mold Details:

Maximum die size: 1300*1000*800mm

Export Area: EU

Delivery time: 45 days

Part Quantity: 7 pcs

Mold Quantity: 6 sets

Number of Processed Sliders: 12 pcs

Mold Material: S136, NAK80, P20, 718, 45#, etc.

Part Material: PVC, PP+GF, POM

Project Leader: Ken Yeo

Key Words

PVC, PP+GF, Air Trap, Shrinkage, SolidWorks

Product detail pictures:

Related Product Guide:

With state-of-the-art technologies and facilities, strict good quality regulate, reasonable cost, exceptional assistance and close co-operation with prospects, we're devoted to supplying the top benefit for our customers for Best Price for Epoxy Injection Molding - Office Chair Back – Uni-Moulding , The product will supply to all over the world, such as: Marseille , European , UAE , Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant experienced knowledge, to develop advanced production equipment and production process , to create the first-call quality goods, reasonable price , high quality of service , quick delivery , to present you create new value .

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.