factory low price Paulson Injection Molding - Plastic ABS Waterproof Shower Pan Mold – Uni-Moulding

factory low price Paulson Injection Molding - Plastic ABS Waterproof Shower Pan Mold – Uni-Moulding Detail:

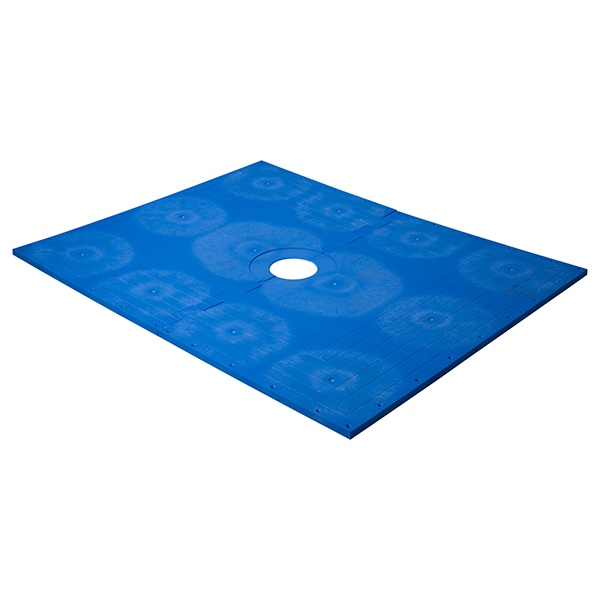

This is a plastic building product applied to the infrastructure of bathroom drainage and waterproofing. Because the houses in the North American market are all wooden frame structures, once the bathroom is not well waterproof, it will face mildew, decay, termites and other related house hazards. Therefore, the development of the shower pan mold and the manufacture of waterproof plastic shower pan can help people solve problems.

Part Details

Part Material: ABS + 15% GF

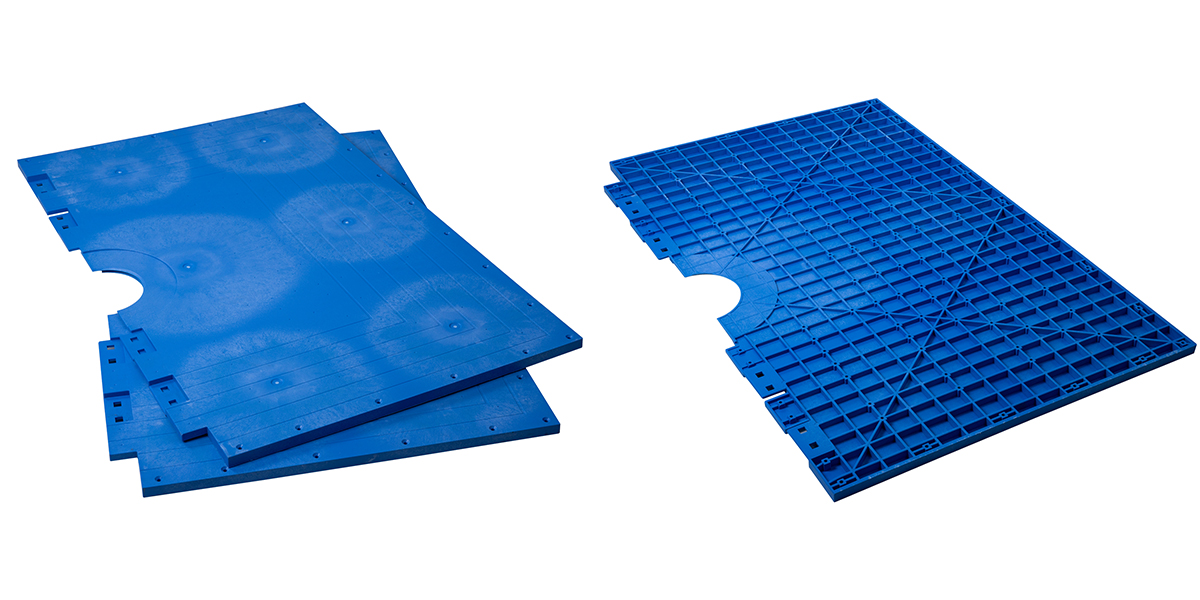

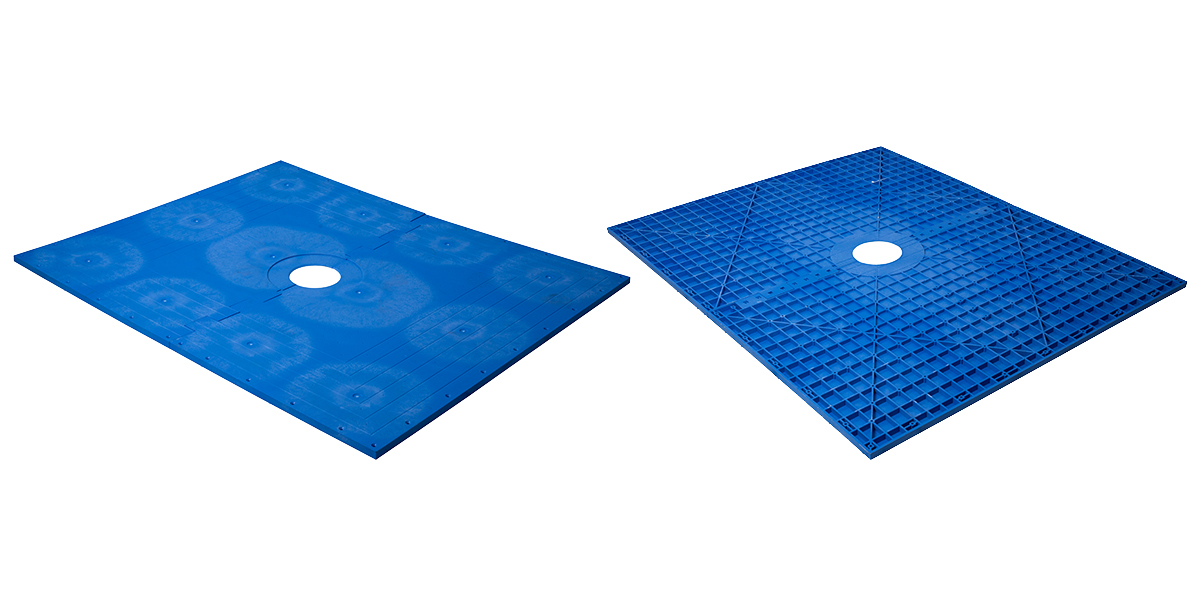

Part Size: 60×48 inches

Part Color: Blue or Grey

Part Weight: 17 KGS

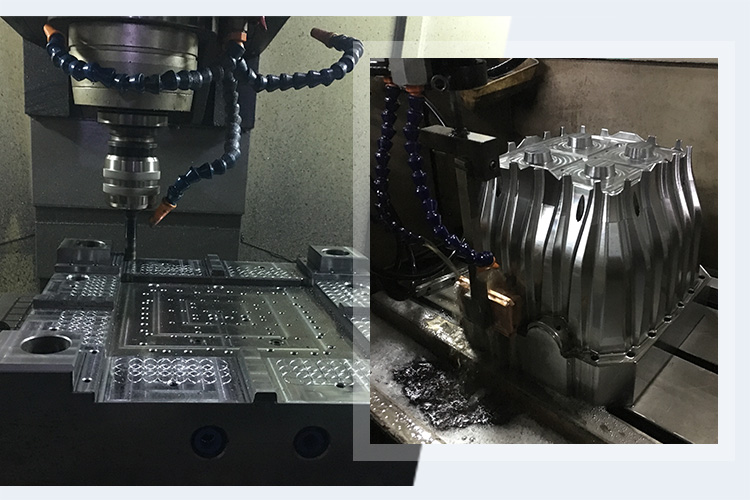

Main Technology and Processes

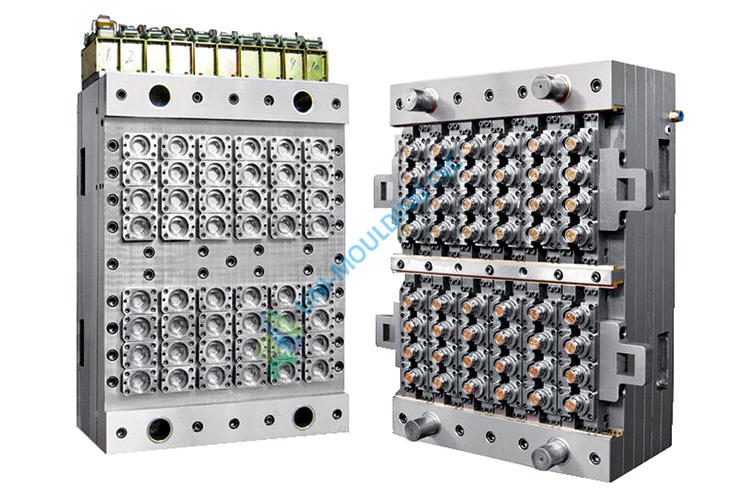

Mold Analysis → Sawing Machine Cutting → Depth Drill → CNC Rough Machining → Heat Treating → Finishing Machining → Wire Cutting → EDM → Polishing → Texture → Mold Assembly and Debugging → Mold Test

Main Challenges & Solutions

C1: In order to save transportation costs, the customer requires that the product size be controlled within a certain range.

S1: Divide the shower pan into two parts, add latch device which can be assembled into a whole

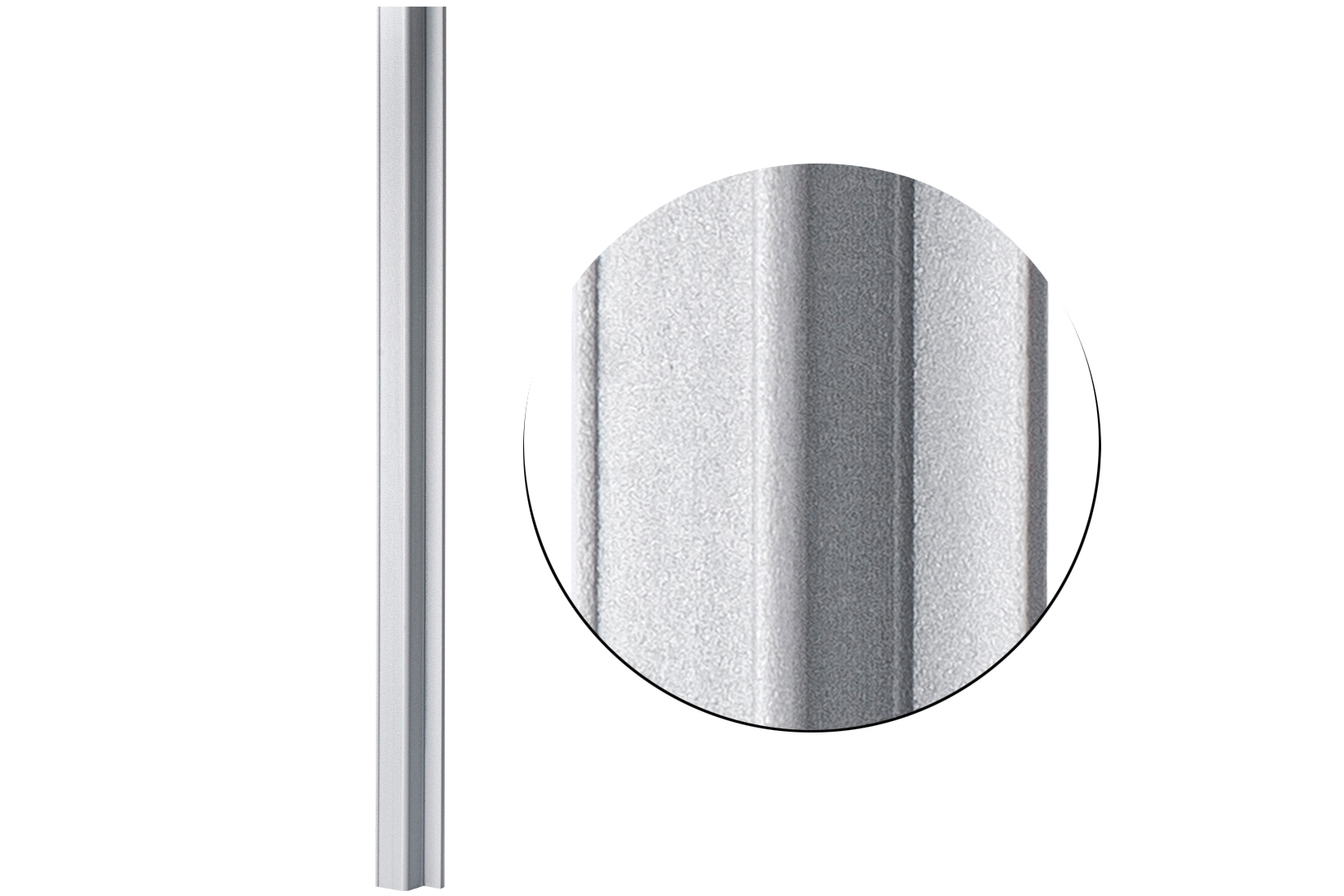

C2: Solve the problem of non sticking tiles.

S2: Change the surface of the shower pan mold from smooth to rough with texture.

C3: Shower Pan deformation and warping.

S3: Basically, all plastic products have problems of deformation, shrinkage and warping. First, we increased the number and size of gate. Second, we increased the size of cooling channels. Third, we tested and used the most appropriate modified materials.

C4: How to solve the problem of shower pan strength?

S4: Properly add glass fiber into materials.

Mold Details

Project Leader: Zach

Mold Type: ABS plastic injection mold

Delivery time: 35 days

Mold Material: P20, 718, 45#, etc.

Product detail pictures:

Related Product Guide:

carry on to boost, to guarantee products excellent in line with market and consumer standard specifications. Our enterprise has a quality assurance system are actually established for factory low price Paulson Injection Molding - Plastic ABS Waterproof Shower Pan Mold – Uni-Moulding , The product will supply to all over the world, such as: Luxemburg , Lesotho , Botswana , We offer OEM services and replacement parts to meet the varying needs of our customers. We offer competitive price for quality products and we will make certain your shipment is handled quickly by our logistics department. We sincerely hope to have the opportunity to meet with you and see how we can help you further your own business.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.