Factory wholesale Custom Injection Mold - Professional Bottle Cap Mold – Uni-Moulding

Factory wholesale Custom Injection Mold - Professional Bottle Cap Mold – Uni-Moulding Detail:

Professional Bottle Cap Mold

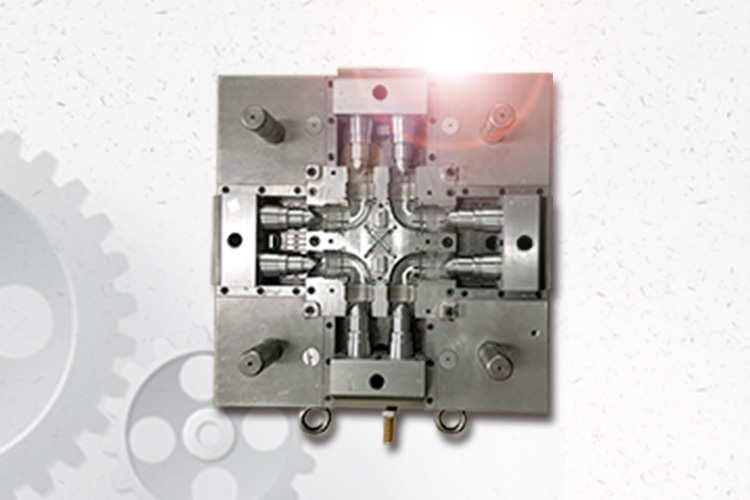

Mold core and cavity are made of S136 steel after heat treatment to ensure hardness and life.

Hot runner system with German heating elements accelerates plastic flow in the molten state, saves materials, and ensures product quality stability.

Use advanced processing equipment to process molds with high precision. In addition, bridge-type three-coordinate measuring instruments and articulated arm measuring instruments are used to precisely control mold size.

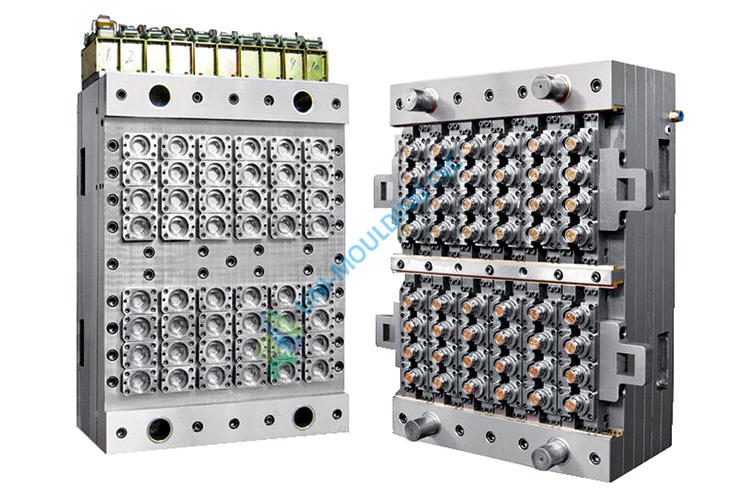

The interchangeable insert saves material costs, and is also convenient for later repairs and maintenance.

We will provide spare parts, such as core/cavity inserts, and other replaceable mold parts, so that damaged parts can be replaced quickly.

After mold manufacturing is completed, a series of running inspection tests are carried out in accordance with our company’s quality standards.

We have a professional team of sales engineers, which can customize mold solutions according to your requirements.

Not only that, we can also build a bottle cap production line-Custom Design Injection Molding Line Set Up. Help you start your production project quickly.

The UNI Difference is seen as our Engineering and Product Development support team is considered to be “mission critical” by our customers. Our engineering team is often perceived as an extension of our customer’s organization, essential to his success in designing and developing new products. With over 10 years of cumulative experience and knowledge, our team can help you reduce the time required for the development cycle, enabling your company to get to market faster and at a lower cost than your competitors. Whether it’s optimizing a plastic part deign or helping you with UNI on a complicated assembly, UNI can help you get to market faster, avoiding costly mistakes.

Product detail pictures:

Related Product Guide:

Our merchandise are commonly recognized and reliable by customers and can meet constantly developing economic and social desires for Factory wholesale Custom Injection Mold - Professional Bottle Cap Mold – Uni-Moulding , The product will supply to all over the world, such as: Saudi Arabia , Seychelles , Victoria , Our company's main products are widely used all over the world; 80% of our products exported to the United States, Japan, Europe and other markets. All stuff sincerely welcome guests come to visit our factory.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.