-

Liquid Silicone Injection Molding Services

Ana amfani da gel na silica sosai a kasuwa saboda baya sakin abubuwa masu guba, yana da laushi da jin dadi, kuma yana da kyawawan kayan jiki da sinadarai a yanayin zafi da ƙananan zafi (-60c ~ + 300c). Akwai 'yan wasu polymers da zasu iya daidaita shi.

Ƙarfin elastomer, mafi kyau fiye da rufewar roba, kyakkyawan rufin lantarki, da juriya ga sinadarai, man fetur, mai, da ruwa, abu mai kyau don jimre wa yanayi mara kyau.

A cikin masana'antu, irin su hatimin mai, maɓallan maɓalli, kayan kariya na lantarki, sassan mota, kayan yau da kullun kamar na'urorin kashe wuta, catheters na wucin gadi, na'urar numfashi, madubin kwadi, takalman fata da sneakers, kwantena abinci, da sauransu.

Idan kuna da kowane ɓangaren sliicone buƙatar samarwa, kawai tuntuɓar mu don samun ƙarin ƙwarewa.

Menene bambanci tsakanin gel silica gel da m silica gel?

Silicone ruwa

Liquid silica gel wani nau'i ne na robar silicone mai tsananin zafi mai ƙarfi. Gel ɗin ruwa ne tare da ruwa mai kyau, saurin vulcanization, mafi aminci da kariyar muhalli, kuma yana iya cika buƙatun matakin abinci gaba ɗaya.

Silica gel mai ƙarfi

M silica gel wani nau'i ne na madaidaicin kayan roba na polymer, wanda ke da halaye na juriya mai zafi, juriya mai sanyi, juriya mai ƙarfi, juriya mai tsauri, tsauri, rufin lantarki, juriya na sinadarai kuma yana da kewayon aikace-aikace mai faɗi.

1. Liquid silica gel da m bayyanar

(1) Kamar yadda sunan ke nunawa, gel silica gel ruwa ne kuma yana da ruwa

(2) M silica gel yana da ƙarfi, ba tare da ruwa ba!

2. Yin amfani da gel silica na ruwa da kuma m silica gel

(1) Gel ɗin siliki na ruwa gabaɗaya ana amfani dashi a samfuran jarirai, samfuran dafa abinci, da kayan aikin likita, waɗanda zasu iya tuntuɓar abinci da jikin ɗan adam kai tsaye.

(2) M silica gel gabaɗaya ana amfani dashi a cikin buƙatun yau da kullun da sassa daban-daban na masana'antu da sassa na mota, da sauransu, kewayon aikace-aikacen yana da faɗin faɗin gaske.

3. Tsaro na m silica gel da ruwa silica gel

(1) Liquid silica gel shine babban fayyace da ingantaccen kayan abinci mai aminci, gyare-gyare ba tare da ƙara wakili mai ɓarna da sauran kayan taimako ba, gyare-gyaren ciyarwa.

(2) M silica gel ne m m kare muhalli abu, forming bukatun don ƙara curing wakili don hanzarta curing forming lokaci, da kuma bude mold ciyar gyare-gyare.

4. Liquid silica gel da m silica gel gyare-gyaren hanya

(1) Silicone ruwa mai narkewa ne na allurar ruwa siliki mai narkewa (LSR): Cikakken suna don yin allurar ruwa mai narkewa, warkarwa kayan aiki don na'urar gyara allurar.

Injection gyare-gyaren inji yana da fasaha tsari da yake da sauqi qwarai, bukatar ba zama tsari na high-zazzabi manne sinadaran, hadawa, blanking, abu da kuma tsari, kawai daya daga cikin ma'aikata dauki kayayyakin), high ainihin kayayyakin (alurar gyare-gyaren allura kafin duk Manual shirin maye gurbinsu da A inji), babban fitarwa (A/B manne hadawa, karkashin wani zafin jiki na 'yan dakiku zuwa siffar), ajiye, ajiye wutar lantarki, ajiye kayan da sauransu da yawa isa yabo, na iya samar da duk high-zazzabi manne samfuran samarwa! Yana da babban ci gaban kayan roba na silicone a cikin 'yan shekaru masu zuwa.

(2) M silica gel gyare-gyaren wani ɗanyen abu ne wanda yake wani yanki ne na m, ta hanyar hadawa na'ura, yankan na'ura a cikin samfurori da alluran gyare-gyaren da ya dace da girman da kauri, sa'an nan kuma a cikin mold, na'ura mai matsa lamba a ƙarƙashin wani zazzabi gyare-gyare. Demoulding da filastik kayayyakin game da guda, kuma bukatar tsaftace mold.

5. Liquid silica gel da m silica gel kayayyakin yadda za a bambanta

Bayyanar silica gel na ruwa yana da girma, ba tare da wari ba, kuma samfurin yana da bakin allurar manne. M pore silica gel m kasa, vulcanizing wakili ko wani murfin vulcanizing kamshi, samfur ba tare da allura baki

-

Tee Joint & P-Trap Mold Yin da Allura Molding Production

Tee hadin gwiwa da gwiwar hannu yadu amfani a cikin ruwa bututu, iska bututu da kuma likita kayan aikin masana'antu, Ya ƙunshi da yawa daban-daban siffofi, girma, da kuma Tsarin.

Don haɗin gwiwa na tee na yau da kullun, tsarin yana da sauƙi, amma ga ƙasashe da kasuwanni daban-daban, masu girma dabam da hanyoyin samun dama sun bambanta.

Duk da haka, la'akari da matsalar dawowar ruwa da wari, an kammala tsarin da ya fi rikitarwa bisa tsarin tsararru, wanda har yanzu yana buƙatar isasshen ƙwarewa a cikin ƙira da samarwa.

A cikin kusan shekaru biyar na haɓakawa, mun taƙaita fiye da nau'ikan tee da bututu masu dacewa da ƙwarewar haɓaka ƙirar ƙira fiye da 80.

Kamar ma'aunin ABS na Amurka da bututun sharar gida na PVC, ya haɗa da kera kayan kwalliyar ABS/PVC da gyare-gyaren tee na nau'ikan masu girma dabam kamar inch 1, 1.5 inch, 2 inch, da 3 inch. Muna kuma da wasu ƙwarewar masana'antu game da PRPR tee ƙiyayya ga abokin ciniki na Afirka ta Kudu (domin taimakawa abokan ciniki su adana kayan haɓaka 12 na ta hanyar maye gurbin mold da saka . Abu mafi ƙalubalanci shine masana'antar ƙira ta hanyoyi uku da samar da samfuran ƙananan kayan aikin likita da tsarin fesa atomatik.

Cikakken Bayani

Kashi Material: ABS, PVC, PPR, PP, PC

Launi na Sashe: Kowane launi

Babban Fasaha da Tsari

Analysis Mold → Yankan Injin Sake → Zurfin Zurfafawa → CNC Rough Machining → Maganin zafi → Kammala Machining → Yankan Waya → EDM → gogewa → Texture → Mold Assembly and Debugging → Gwajin Mold

Babban Kwarewar Ci gaban Mold

P Trap Mold, Tee PVC Fitting Connector (1/2 ", 3/4", 1", 1-1/4", 1-1/2", 2", 3"), 2 in. Marasa Sauti DWV Sanitary Tee, 2 in. DWV PVC P-Trap tare da Solvent Weld Joint, 2 inch Plain 90 Degree PVC Tee

Cikakken Bayani

Jagoran Aikin: Zach

Nau'in Motsi: Filastik allura mold

Lokacin bayarwa: kwanaki 20-45

Mold Material: NAK80, S136, 136H, 718H, P20, 718, 45#, da dai sauransu.

-

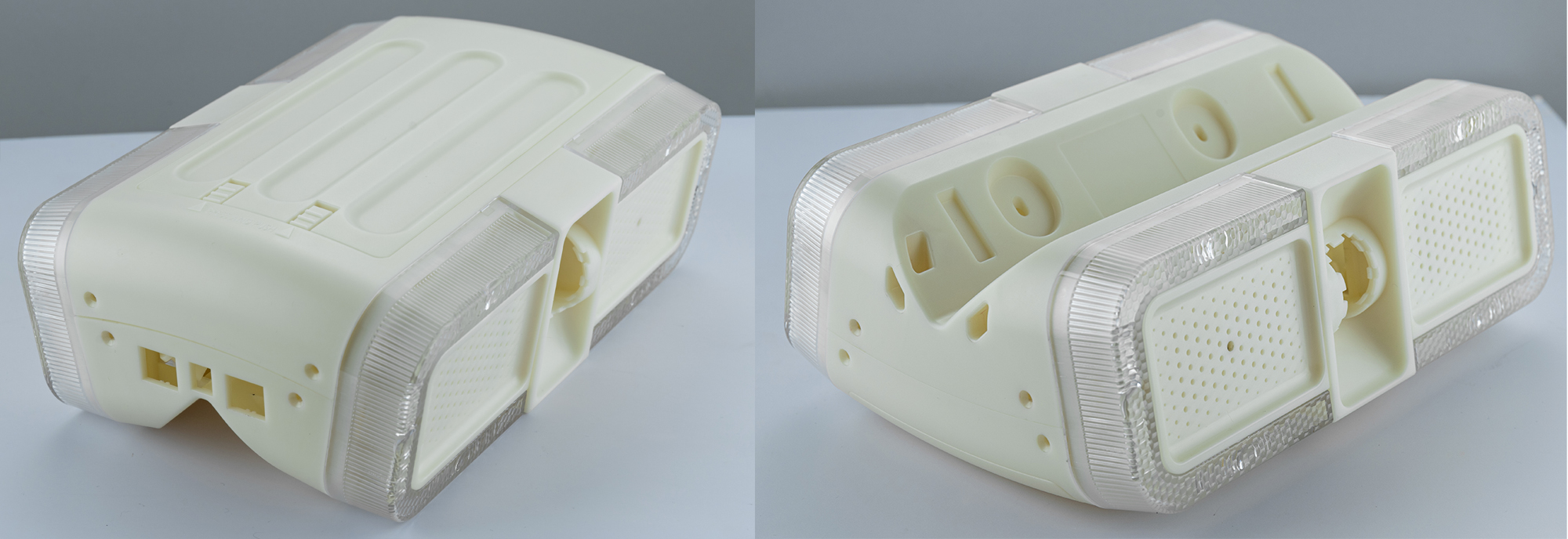

Ci gaban Case Mold na Baturi da Ayyukan Gyaran Batir na Shell ABS

Batirin ya saita mu da ake amfani dashi sosai a cikin masana'antar kera motoci da babura, Ya ƙunshi nau'ikan ƙira da girma dabam dabam.

A cikin shekaru 9, Uni Molding sun haɓaka fiye da saiti 50 na alluran baturi da nau'ikan nau'ikan ɓangaren baturi. A cikin yanayin ƙirar baturi, haɓaka ƙirar ƙirar baturi galibi yana da alaƙa da ƙirar ƙirar mai zafi mai zafi na tushen baturin baturi, saman murfin baturin baturi, da nau'ikan nau'ikan tagulla na jan karfe.

A cikin aiwatar da ci gaba da samar da haɗin gwiwar, koyaushe muna koyo game da ƙa'idar aiki na baturi da kuma taka tsantsan don taron hukumar da'ira. Baya ga magance matsalar ci gaban ƙirar harsashin baturi, yana kuma iya taimakawa haɗa baturi da gwaji.

Cikakken Bayani

Material: ABS, Brass

Girman ciki: 106 × 63 × 61 mm; 143 × 79.5 × 73.5 mm; 145 × 64 × 111 mm; 144×80×110 mm; 107×68×82 mm; 105 × 52 × 68 mm; 105 × 26 × 69 mm; 105 × 68 × 108 mm;

Launi na Sashe: Kowane launi

Babban Fasaha da TsariAnalysis Mold → Yankan Injin Sake → Zurfin Zurfafawa → CNC Rough Machining → Maganin zafi → Kammala Machining → Yankan Waya → EDM → gogewa → Texture → Mold Assembly and Debugging → Gwajin Mold

Kariya don haɓaka tsarin magudanar ƙasa.

A cikin gyare-gyaren allura na ƙirar baturi, an magance matsalar ƙancewar samfurin da daidaituwa;

Yi amfani da ABS mai ɗaukar wuta don maye gurbin ABS na yau da kullun don gyare-gyaren allura;

Na'urar tagulla stamping na chrome ne sannan kuma ABS akan gyaran allura, wanda zai fi magance matsalar hatimin baturi.

Cikakken Bayani

Jagoran Aikin: Zach

Nau'in Mold: Filastik allura mold, Stamping Die, Plastic Rubber Mould, Hot Chamber mutu simintin gyaran kafa, kumfa Mould, Latsa Tool Stamping mutu Punch mutu,

Lokacin bayarwa: kwanaki 20-45

Mold Material: NAK80, S136, 136H, 718H, P20, 718, 45#, da dai sauransu.

-

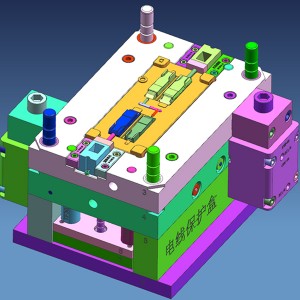

Tsarin ƙararrawa na ɗakunan ajiya na hankali

UNI MOLDING yana da shekaru 15 na gwaninta a cikin ci gaban allurar filastik, musamman a cikin kayan aikin lantarki harsashi mold, ƙirar firam ɗin tallafi, na'urar filastik filastik. A cikin ci gaba da ci gaba da ci gaba, yawancin abokan ciniki suna haɓaka samfuran su, daga simintin ƙarfe zuwa tsarin hatimin ƙarfe, daga sarrafa ƙarfe zuwa gyare-gyaren filastik. Muna ci gaba da haɓaka matsalolin da suka danganci lalata juriya, juriya mai girma da juriya na UV na ƙirar filastik don yin aikin samfuran filastik fiye da sauran samfuran tsari. A cikin sauri ci gaba a cikin 'yan shekarun nan, mun ɓullo da filastik Tantancewar fiber winding akwatin mold; Kasan layin na gani na USB shaft m harsashi mold; Goyon bayan siginar tashar watsa sigina.

Cikakken BayaniSashi na Material: ABS, PVC, PC, PP, BRASS, BAKIN KARFE 304/316 Girman Sashe: 255 * 176 * 100 mm Sashe Launi: Kowane launiBabban Fasaha da TsariAnalysis Mold → Yankan Injin Sake → Zurfin Zurfafawa → CNC Rough Machining → Maganin zafi → Kammala Machining → Yankan Waya → EDM → gogewa → Texture → Mold Assembly and Debugging → Gwajin MoldKariya don haɓaka tsarin magudanar ƙasa.

Cikakken BayaniSashi na Material: ABS, PVC, PC, PP, BRASS, BAKIN KARFE 304/316 Girman Sashe: 255 * 176 * 100 mm Sashe Launi: Kowane launiBabban Fasaha da TsariAnalysis Mold → Yankan Injin Sake → Zurfin Zurfafawa → CNC Rough Machining → Maganin zafi → Kammala Machining → Yankan Waya → EDM → gogewa → Texture → Mold Assembly and Debugging → Gwajin MoldKariya don haɓaka tsarin magudanar ƙasa.- Dole ne a yi murfin siginar da kayan watsa haske mai ƙarfi na acrylic, wanda zai sami sakamako iri ɗaya da fitilar;

- Muna amfani da gwaninta na ruwan sama mai ruwan sama don tunani don inganta ƙaho mai sauti;

- Domin motsa rarrabuwar ƙararrawa, muna amfani da gyare-gyaren allura don nannade ƙaƙƙarfan maganadisu, kuma muna amfani da jan hankali na maganadisu don gyara ƙararrawa;

- Ya kamata a yi la'akari sosai da yankewa da nakasar sassa na filastik, ɓangarorin ɓarna na bakin karfe, juriyar juzu'i na allunan da'ira, da tsare-tsare na cikin gida na samfuran ƙararrawa.

Cikakken BayaniJagoran Aikin: Ken Mold Nau'in: Tsarin alluran filastik, Stamping Die, Plastic Rubber Mould, Hot Chamber Die Casting, Foaming Mould, Press Tool Stamping Die Punch Die, Lokacin bayarwa: 20-45 days Mold Material: NAK80, S136, 136H, 718H , P20, 718, 45#, da dai sauransu.

Cikakken BayaniJagoran Aikin: Ken Mold Nau'in: Tsarin alluran filastik, Stamping Die, Plastic Rubber Mould, Hot Chamber Die Casting, Foaming Mould, Press Tool Stamping Die Punch Die, Lokacin bayarwa: 20-45 days Mold Material: NAK80, S136, 136H, 718H , P20, 718, 45#, da dai sauransu. -

Filastik Mold Maker da Allura Molding Sabis na Amurka Kasuwar don Filastik Cable Cover

Uni Molding sun yi fiye da 30 sets na daban-daban junction akwatin mold sets, ciki har da jerin optoelectronic alaka roba molds, kamar high-ƙarfin wuta na USB junction akwatin mold, Tantancewar fiber junction akwatin mold, mita harsashi mold, waya dangane kariya mold, da dai sauransu Muna da gogewa da yawa a masana'antar ƙera akwatin junction.

Kodayake murfin kebul a cikin wannan aikin yana da ƙananan, yawancin bayanai suna buƙatar la'akari. Saboda wannan samfur ne da aka sake amfani dashi sau da yawa, baya ga rufin sa, rigakafin tsufa, juriya na UV, hana ruwa da sauran abubuwan da ke da alaƙa, yakamata a yi la'akari da sassaucin sa don sake amfani da shi.

Cikakken Bayani

Material: PP+UV

Launi na Sashe: Baƙar fata

Nauyin sashi: 8g

Babban Fasaha da Tsari

Analysis Mold → Yankan Injin Sake → Zurfin Zurfafawa → CNC Rough Machining → Maganin zafi → Kammala Machining → Yankan Waya → EDM → gogewa → Texture → Mold Assembly and Debugging → Gwajin Mold

Babban Kalubale & Magani

C1: tsufa na samfurin filastik;

S1: Sanya sashin launi zuwa baki mai duhu kuma ƙara UV, wanda zai iya tsayayya da tsufa da UV yadda ya kamata.

C2: Tabbatar cewa ɓangaren yana buƙatar ninka akai-akai ba tare da karya ba kuma ya zama fari;

S2: Yi amfani da PP ba-silicon copolymerized PP azaman kayan asali, kuma ƙara wasu kayan taimako daidai don cimma mafi kyawun sakamako na PP (Kyakkyawan ingantaccen aiki, babban ƙarfi, babban ƙarfi, tsayayyar zafi mai kyau, kwanciyar hankali mai girma, kyakkyawan ƙarancin zafin jiki mai ƙarfi. (kyakkyawan sassauci), kyakkyawar fayyace, da kyalli mai kyau.)

Cikakken Bayani

l Jagoran Ayyuka: Zach

l Nau'in Motsi: PP filastik allura mold

l Lokacin bayarwa: kwanaki 28

l Girman samfur: 10*6*3

l Girman Girma: 400x280x360 mm

l Kogon Motsi: 2 cavities

l Mold Main Material: S136

l Mold Material: 718H, P20, 718, 45#, da dai sauransu.

l Tsarin Allurar Mold: Ƙofar Nuni

l Tsawon Lokaci: 12"

-

Allurar Filastik Shawa Mai Ruwa Magudanar Ruwa Tambarin Mutuwar Motsi

UNI MOLDING ya ci gaba a cikin samar da ingantattun gyare-gyaren shawa mai inganci kuma musamman ma babban fasahar stamping mold, simintin gyare-gyare, gyare-gyaren filastik tare da maganin gyare-gyare. UNI MOLDING ya ci gaba a cikin samar da ingantattun gyare-gyaren shawa mai inganci kuma musamman ma babban fasahar stamping mold, simintin gyare-gyare, gyare-gyaren filastik tare da maganin gyare-gyare.

Har ila yau, muna ba da bayani na al'ada da aka yi don R & D da zane-zane na filastik filastik da sabon haɓaka samfurin tare da tebur da magudana a cikin cikakken saiti, bayyanar zane-zane yana ba da shawarar da sauransu. Don haka, UNI MOLDING ya shahara ga fasahar R&D ɗin mu a cikin tsarin tsarin shawa da kuma haɓaka ƙirar ƙirar filastik ɗin mu.

Cikakken Bayani

Sashi na Material: ABS, PVC, PC, PP, BRASS, BAKIN KARFE 304/316, BRASS, ZINK, Aluminum

Girman Sashe: 3.5 inci, 4 inci, 6 inci magudanar ruwa; 6/12/24/28/30/32/36/48 inci magudanar layin layi

Launi na Sashe: Kowane launi

Babban Fasaha da Tsari

Analysis Mold → Yankan Injin Sake → Zurfin Zurfafawa → CNC Rough Machining → Maganin zafi → Kammala Machining → Yankan Waya → EDM → gogewa → Texture → Mold Assembly and Debugging → Gwajin Mold

Mata na mutuwa, sukan jefa mold, filastic fashion m, castmuri mai zafi, kumfa

Kariya don haɓaka tsarin magudanar ƙasa.

- Zana wani gangare don sauƙaƙe magudanar ruwa;

- Ya kamata a yi la'akari da girma da kayan aikin bututun magudanar ruwa a cikin ƙasashe da yankuna daban-daban;

- Hana bakin karfe 304 daga rusting da electroplating Layer daga fadowa;

- Daidaita kusurwar tsayi a lokacin shigarwa;

- Cikakkun takaddun shaida da kayan aikin da suka dace don tabbatar da takaddun shaida;

Cikakken Bayani

Jagoran Aikin: Zach

Mold Nau'in: Filastik allolin Mold, Mata Mata Masa, Filibar Mold

Lokacin bayarwa: kwanaki 20-45

Mold Material: NAK80, S136, 136H, 718H, P20, 718, 45#, da dai sauransu.

-

Filastik ABS Mai hana ruwa Shawa Pan Mold

Wannan samfurin ginin filastik ne da aka yi amfani da shi ga kayan aikin magudanar ruwa da kuma hana ruwa. Domin gidajen da ke kasuwannin Arewacin Amurka duk gine-ginen katako ne, da zarar gidan wanka ba shi da ruwa mai kyau, zai fuskanci mildew, ruɓe, tururuwa da sauran haɗarin gida masu alaƙa. Saboda haka, ci gaban kwanon rufin shawa da kuma samar da kwanon filastik mai hana ruwa na iya taimakawa mutane su magance matsalolin. Sashe Cikakkun bayanai Sashe na Material: ABS + 15% GF Girman Sashe: 60×48 inci... -

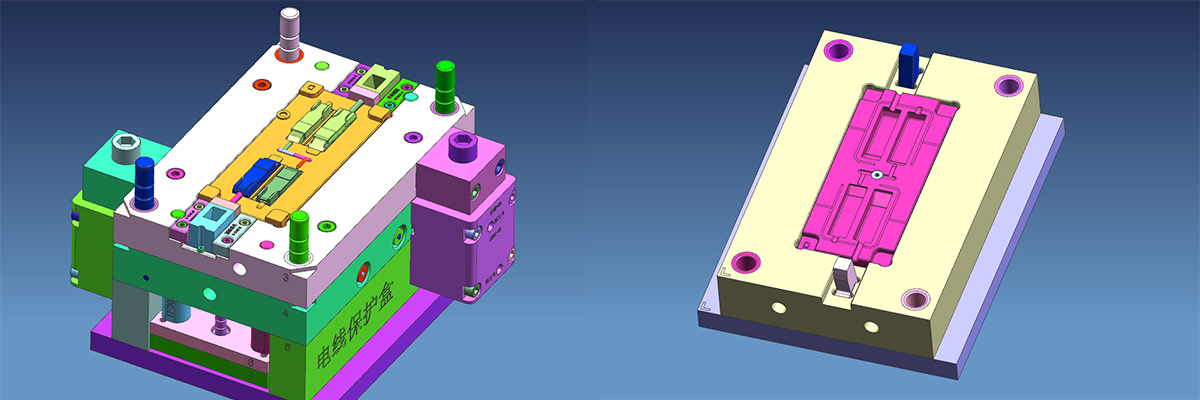

Me game da Multi Cavity Injection Molds Yin

Multi rami mold ne bisa ga girman da ikon samar, samfurin tsarin. Yana ƙayyade adadin da ya dace na cavities, ƙarin madaidaicin ƙira, wahalar sarrafawa. Mafi girman farashi na kogon mold. Koyaya, farashin rukunin sassan alluran ya ragu sosai.

-

ABS extruded profile

ABS extrusion tsiri ne yadu amfani a ginin kayan, kofa frame, ado frame da photo frame. Firam ɗin extruded ABS yana da ƙarfi mai kyau, tauri da juriya na lalata, kuma yana da kyakkyawar gasa ta kasuwa a farashi. A cikin shekaru da yawa na bincike, ci gaba da gwajin mu kamfanin, mu kai-samar ABS extruded frame ya fi takwarorinsu a kasuwa a cikin ƙarfi, tauri, lalata juriya da kuma aesthetics. Ya yi babban ci gaba a kasuwannin Turai kuma ana amfani da shi sosai wajen adon gida na Turai.

-

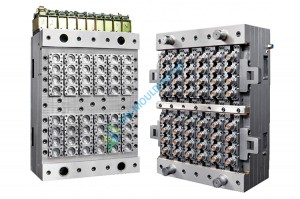

Ƙwararrun Ƙwararrun Ƙwararrun Ƙwararru

Uni-Moulding ya ƙware wajen samar da nau'ikan ƙirar hular kwalba daban-daban. Muna da cikakken R & D tawagar, zane sashen, high-madaidaici aiki kayan aiki, ingancin dubawa sashen da bayan-tallace-tallace sabis tawagar don tabbatar da kyakkyawan ingancin kowane biyu molds. Tare da shekaru 15 na gwaninta mai wadata, mun yi nau'ikan iyakoki iri-iri, irin su manyan iyakoki, ƙwanƙolin baka, iyalai na gallon biyar, iyakoki na kwaskwarima, da sauransu (har zuwa 128 cavities). Kayan kwalliyar kwalliyar kwalliyarmu tana da fa'idodi masu zuwa.

-

Fitar 3D

Tare da haɓakawa da girma na fasahar bugu na 3D, an yi amfani da fasahar bugu na 3D sau da yawa a cikin ƙirar samfuri da aikace-aikacen Uni-Molding. Ana amfani da shi sosai a magani, wasanni da kayan gini. Kwasa-kwasan wasan golf na cikin gida, na'urorin jinkirin wasan ƙwallon baseball, kayan adon gefen gado, ɗamarar masana'antu, kwantena masu aunawa, hannayen kofa da taga, kwalkwali, abin rufe fuska, da sauransu.

Duk da haka, 3D bugu har yanzu yana da wasu gazawar fasaha. -

Shugaban Ofishin Baya

Mold Tushe: DME

Mold Material: S136 Zafi Magani

Material: TPU