Ua hana ʻo Uni Molding i ʻoi aku ma mua o 30 mau pūʻulu o nā pahu pahu pahu hui like ʻole, me kahi pūʻulu o ka optoelectronic pili i ka plastic mold, e like me ke kiʻekiʻe-voltage cable junction box mold, optical fiber junction box mold, mika shell mold, wire connection protection mold, etc. .

ʻOiai he liʻiliʻi ka uhi uwea ma kēia papahana, pono e noʻonoʻo ʻia nā kikoʻī he nui. No ka mea he huahana kēia i hoʻohana hou ʻia no nā manawa he nui, ma kahi o kona insulation, anti-aging, UV resistance, waterproof a me nā mea pili ʻē aʻe, pono e noʻonoʻo ʻia kona maʻalahi no ka hoʻohana hou ʻana.

Māhele kikoʻī

Māhele Māhele: PP + UV

Kala ʻāpana: ʻEleʻele

Kaumaha ʻāpana: 8g

ʻenehana nui a me nā kaʻina hana

Nānā Mold → ʻoki ʻana i ka mīkini ʻoki → Drill hohonu → CNC Rough Machining → Heat Treating → Finishing Machining → Wire Cutting → EDM → Polishing → Texture → Mold Assembly and Debugging → Mold Test

Nā Luʻi Nui a me nā Hoʻonā

C1: ʻO ka ʻelemakule o ka huahana plastik;

S1: E hana i ka ʻāpana kala i ʻeleʻele ʻeleʻele a hoʻohui i ka UV, hiki ke pale pono i ka wā kahiko a me UV.

C2: E hōʻoia i ka ʻāpana pono e pelu pinepine ʻia me ka haki ʻole a keʻokeʻo;

S2: E hoʻohana i ka PP no-silicon copolymerized ma ke ʻano he kumu kumu, a hoʻohui i kekahi mau mea kōkua kūpono e hoʻokō ai i ka hopena maikaʻi loa o ka PP (Maikaʻi piha piha, ikaika kiʻekiʻe, rigidity kiʻekiʻe, kūpaʻa wela maikaʻi, kūpaʻa maikaʻi, ʻoi aku ka paʻakikī haʻahaʻa haʻahaʻa. (ʻoluʻolu maikaʻi), ʻikea maikaʻi, a me ka nani o ka nani.)

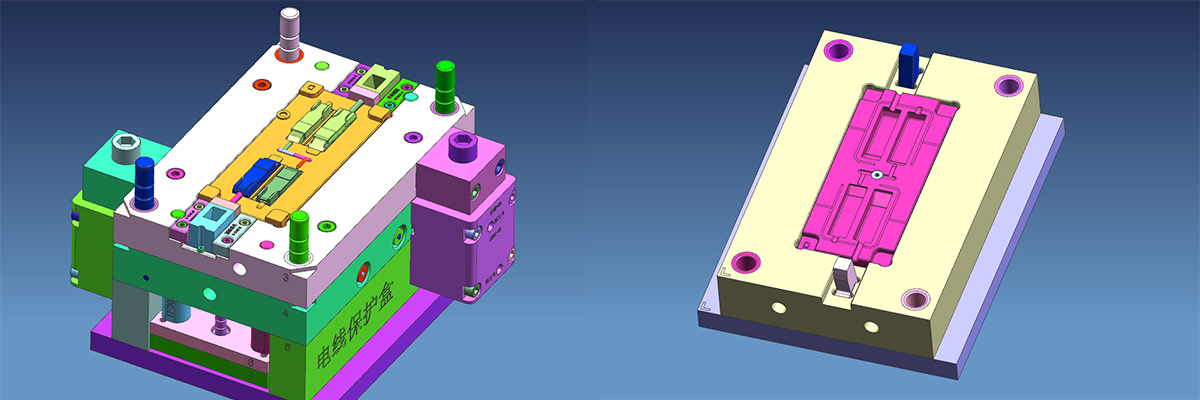

ʻIkepili Mold

l Alakaʻi Papahana: Zach

l Mold Mold: PP plastic injection mold

l Hoʻouna manawa: 28 lā

l Nui Huahana: 10*6*3

l Nui Mold:400x280x360 mm

l Mold Cavity: 2 lua

l Mold Main Material: S136

l Mold Material: 718H, P20, 718, 45 #, etc.

l Mold Injection System: puka kiko

l Manawa Kaapuni Mold: 12”