-

ʻO nā lawelawe hoʻoheheʻe wai silicone

Hoʻohana nui ʻia ka silica gel ma ka mākeke no ka mea ʻaʻole ia e hoʻokuʻu i nā mea ʻawaʻawa, loaʻa kahi paʻi palupalu a ʻoluʻolu, a loaʻa nā waiwai kino a me nā kemika maikaʻi i nā wela kiʻekiʻe a me nā haʻahaʻa haʻahaʻa (-60c~+300c). Aia kekahi mau polymers ʻē aʻe i hiki ke hoʻohālikelike me ia.

ʻO ka elastomer ikaika, ʻoi aku ka maikaʻi ma mua o ka hoʻopaʻa ʻana i ka lāʻau, ka insulation uila maikaʻi loa, a me ke kūpaʻa ʻana i nā kemika, nā wahie, ka aila, a me ka wai, kahi mea maikaʻi e hoʻokō ai i nā kaiapuni ʻino.

I loko o ka ʻoihana, e like me nā sila aila, nā kī kī, nā mea hoʻokalakupua uila, nā ʻāpana kaʻa, nā mea e pono ai i kēlā me kēia lā e like me nā pacifiers, nā catheters artificial, respirators, nā aniani frog, nā kāmaʻa ʻili a me nā sneakers, nā ipu meaʻai, etc.

Inā loaʻa iā ʻoe kahi ʻāpana sliicone e pono ai e hana, e hoʻokaʻaʻike mai iā mākou e loaʻa hou ka ʻike.

He aha ka ʻokoʻa ma waena o ka silica gel wai a me ka silica gel paʻa?

Silikoni wai

ʻO ka wai silica gel kahi ʻano paʻa paʻa kiʻekiʻe-mehana vulcanized silicone rubber. He gel wai ia me ka wai maikaʻi, ka vulcanization wikiwiki, palekana a me ka palekana o ke kaiapuni, a hiki ke hoʻokō pono i nā koi o ka papa meaʻai.

gel silica paʻa

ʻO ka silica gel paʻa he ʻano mea saturated polymer elastic material, nona nā hiʻohiʻona o ke kūpaʻa wela kiʻekiʻe, ke kūpaʻa anuanu, ka pale ʻana o ka solvent, ka pale ʻana i ka paʻa ʻana, ka anti-sticking, ka insulation uila, ke kūpaʻa kemika a loaʻa ka laulā noi.

1. Liquid silica gel a me ka helehelena paʻa

(1) E like me ka inoa e hōʻike nei, he wai ka wai silica gel a loaʻa ka wai

(2) Paʻa ka silica gel paʻa, me ka wai ʻole!

2. ʻO ka hoʻohana ʻana i ka gel silica wai a me ka gel silica paʻa

(1) Hoʻohana pinepine ʻia ka gel silica wai i nā huahana pēpē, nā huahana kīhini, a me nā lako olakino, hiki ke hoʻopili pololei i ka meaʻai a me ke kino kanaka.

(2) Hoʻohana maʻamau ka silica gel paʻa i nā mea e pono ai i kēlā me kēia lā a me nā ʻāpana ʻāpana ʻenehana a me nā ʻāpana kaʻa, a me nā mea ʻē aʻe.

3. Ka palekana o ka silica gel paʻa a me ka wai silica gel

(1) Liquid silica gel he kiʻekiʻe ka ʻike a me ka palekana kiʻekiʻe o ka meaʻai meaʻai, hoʻoheheʻe me ka ʻole o ka hoʻohui ʻana i ka mea vulcanizing a me nā mea kōkua ʻē aʻe, hoʻopaʻa ʻia i ka hoʻoheheʻe ʻana.

(2) ʻO ka silica gel paʻa kahi mea palekana kaiapuni, pono e hoʻohui i kahi mea ho'ōla e hoʻolalelale i ka manawa hoʻōla, a wehe i ka hoʻoheheʻe ʻana i ka ʻai.

4. ʻO ke ʻano hana hoʻoheheʻe silica gel a paʻa

(1) ʻO ka silikoni wai ka hoʻoheheʻe ʻia ʻana o ka ʻili silikoni wai (LSR): inoa piha no ka hoʻoheheʻe ʻana i ka ʻili silikoni wai, nā mea hana hoʻōla no ka mīkini hoʻoheheʻe ʻia.

ʻO ka mīkini hoʻoheheʻe i hoʻoheheʻe ʻia he hana ʻenehana maʻalahi loa, ʻaʻole pono ke kaʻina hana o nā mea hoʻonaninani kiʻekiʻe, ka hui ʻana, ka blanking, nā mea a me ke kaʻina hana, hoʻokahi wale nō o nā limahana e lawe i nā huahana), nā huahana kiʻekiʻe (injection molding ma mua o nā mea āpau. Hoʻololi ʻia ka polokalamu manual e A mīkini), kiʻekiʻe kiʻekiʻe (A / B glue hui ʻana, ma lalo o kahi mahana no kekahi mau kekona e hoʻohālikelike ai), mālama, mālama i ka uila, mālama i nā mea a me nā mea he nui, hiki ke hana i nā mea āpau kiʻekiʻe. huahana hana! ʻO ia kahi hoʻomohala kumulāʻau silicone rubber i nā makahiki e hiki mai ana.

(2) ʻO ka hoʻoheheʻe ʻia ʻana o ka silica gel paʻa kahi ʻāpana paʻa, ma o ka hui ʻana o ka mīkini hui, ʻoki ʻia ka mīkini ʻoki i nā huahana a hoʻoheheʻe ʻia i ka nui kūpono a me ka mānoanoa, a laila i loko o ka mold, kaomi ʻana i ka mīkini ma lalo. kahi hoʻoheheʻe wela. ʻO ka demoulding a me nā huahana plastik e pili ana i ka like, pono hoʻi e hoʻomaʻemaʻe i ka ʻōpala.

5. Liquid silica gel a me nā huahana silica gel paʻa pehea e ʻike ai

He kiʻekiʻe ka ʻike wai silica gel, ʻaʻohe ʻala, a loaʻa i ka huahana kahi waha injection glue. Paʻa paʻa pore silica gel alohilohi lalo, vulcanizing agent a i ʻole kekahi uhi ʻala vulcanizing agent, kahi huahana me ka waha ʻole.

-

Tee Hui & P-Trap Mold Making and Injection Molding Production

Hoʻohana nui ʻia ka hui ʻana a me ka kuʻekuʻe i ka paipu wai, ka ea a me ka ʻoihana lāʻau lapaʻau.

No ka hui pū maʻamau, maʻalahi loa ke ʻano, akā no nā ʻāina like ʻole a me nā mākeke, ʻokoʻa nā ʻano like a me nā ala komo.

Eia nō naʻe, i ka noʻonoʻo ʻana i ka pilikia o ka hoʻihoʻi ʻana o ka wai a me ka ʻala, ua hoʻopau ʻia kahi ʻano paʻakikī ma ke kumu o kahi hoʻonohonoho o nā mold, e koi ana i ka ʻike kūpono i ka hoʻolālā a me ka hana ʻana.

I loko o kā mākou ʻelima mau makahiki o ka hoʻomohala ʻana, ua hōʻuluʻulu mākou ma mua o 80 mau ʻano o ka tee a me ka paipu kūpono i ka hoʻomohala ʻana i ka ʻike.

E like me ka ʻAmelika maʻamau ABS a me ka paipu ʻōpala PVC, pili ia i ka hana ʻana i nā molds tee ABS/PVC a me ka hoʻoheheʻe ʻana i ka tee o nā ʻano nui like ʻole me 1 iniha, 1.5 iniha, 2 ʻīniha, a me 3 iniha. Loaʻa iā mākou kekahi ʻike hana hana no ka PPR tee mold no kā mākou mea kūʻai aku ma ʻApelika Hema (I mea e kōkua ai i nā mea kūʻai aku e mālama i nā kumukūʻai hoʻomohala mold, ma ke kumu o ʻekolu mau ʻāpana o nā mold, ua ʻike mākou i ka hana ʻana o nā ʻāpana tee 12 ma ka hoʻololi ʻana i ka mold core a me nā hoʻokomo) . ʻO ka mea paʻakikī loa, ʻo ia ka hana ʻana i nā mold ʻekolu a me ka hana ʻana i nā huahana o nā mea lapaʻau liʻiliʻi liʻiliʻi a me ka ʻōnaehana hoʻoheheʻe aunoa.

Māhele kikoʻī

Mahele Mahele: ABS, PVC, PPR, PP, PC

Kala ʻāpana: ʻO kēlā me kēia kala

ʻenehana nui a me nā kaʻina hana

Nānā Mold → ʻoki ʻana i ka mīkini ʻoki → Drill hohonu → CNC Rough Machining → Heat Treating → Finishing Machining → Wire Cutting → EDM → Polishing → Texture → Mold Assembly and Debugging → Mold Test

ʻIke Hoʻomohala Nui

P Trap Mold, Tee PVC mea hoʻohui (1/2", 3/4", 1", 1-1/4", 1-1/2", 2", 3") , 2 in. Glueless Soundproof DWV Sanitary Kahu, 2 'īniha. DWV PVC P-Trap me Solvent Weld Hui, 2″ Plain 90 Degree PVC Tee

ʻIkepili Mold

Alakaʻi Papahana: Zach

Mold Mold: Mold injection plastic

Ka manawa hoʻouna: 20-45 mau lā

Mold Material: NAK80, S136, 136H, 718H, P20, 718, 45 #, etc.

-

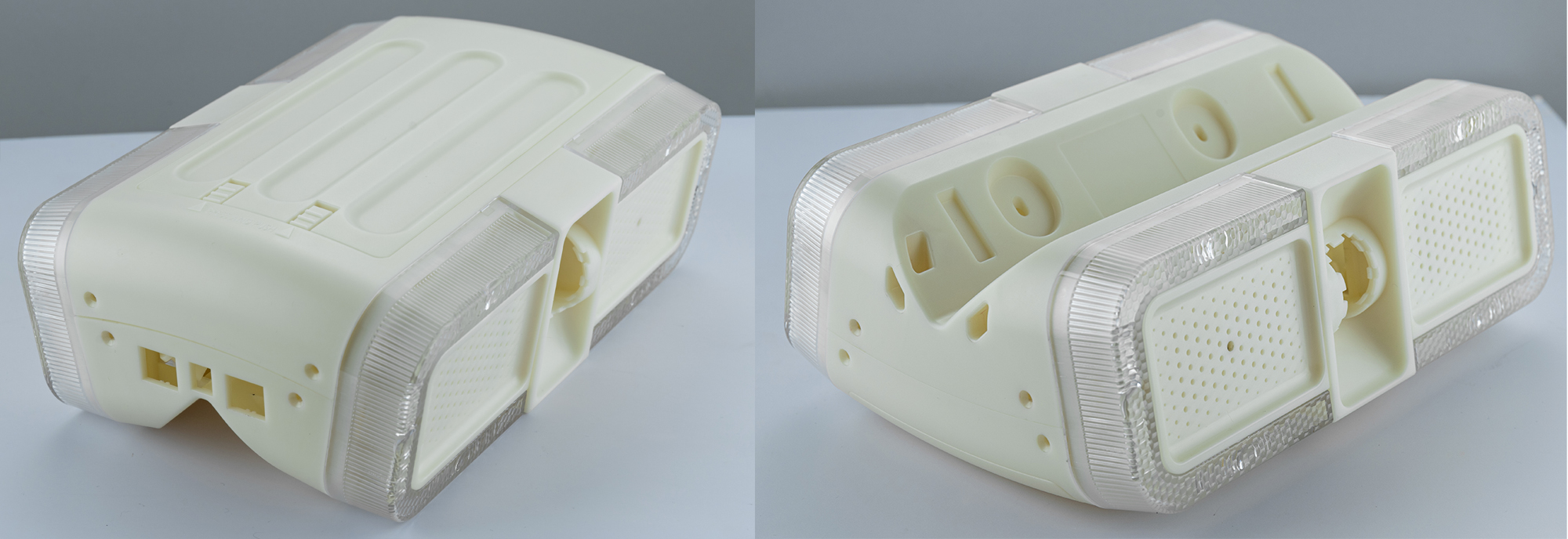

Hoʻomohala ʻana i ka pahu pahu pahu a me nā lawelawe ʻo ABS Battery Shell Injection Molding

Hoʻohana nui ʻia ka pākaukau iā mākou i ka ʻoihana kaʻa a me ka ʻoihana kaʻa, pili ia i nā ʻano like ʻole a me nā ana.

I loko o nā makahiki 9, ua hoʻomohala ʻo Uni Molding ma mua o 50 sets battery case injection mold and other battery case part mold. Ma ka hoʻomohala ʻana o ka pahu pahu pahu e pili nui ana i ka mold hoʻoheheʻe wela o ka waihona pahu pahu, ka poʻi ma luna o ka uhi pahu pahu, a me ka hoʻoheheʻe ʻana o nā ʻāpana keleawe.

Ma ke kaʻina hana o ka hana hoʻomau, aʻo mau mākou e pili ana i ke kumu hana o ka pākaukau a me ka mālama ʻana no ka hui ʻana o ka papa kaapuni. Ma waho aʻe o ka hoʻoponopono ʻana i ka pilikia o ka hoʻomohala ʻana i ka puʻupuʻu puʻupuʻu, hiki iā ia ke kōkua i ka hui ʻana a me ka hoʻāʻo ʻana.

Māhele kikoʻī

Māhele Māhele: ABS, keleawe

Nā Ana o loko: 106×63×61 mm; 143×79.5×73.5 mm; 145×64×111 mm; 144×80×110 mm; 107×68×82 mm; 105×52×68 mm; 105×26×69 mm; 105×68×108 mm;

Kala ʻāpana: ʻO kēlā me kēia kala

ʻenehana nui a me nā kaʻina hanaNānā Mold → ʻoki ʻana i ka mīkini ʻoki → Drill hohonu → CNC Rough Machining → Heat Treating → Finishing Machining → Wire Cutting → EDM → Polishing → Texture → Mold Assembly and Debugging → Mold Test

ʻO ka mālama ʻana no ka hoʻomohala ʻana i ka ʻōnaehana hoʻoheheʻe papahele.

I ka hoʻoheheʻe ʻia ʻana o ka pahu pahu pahu, ua hoʻoholo nui ʻia ka pilikia o ka emi ʻana o ka ʻili a me ka hoʻonohonoho ʻana;

E hoʻohana i ka ABS pale ahi e pani i ka ABS maʻamau no ka hoʻoheheʻe ʻana;

ʻO ka electrode stamping keleawe he chrome plated a laila ʻo ABS ma luna o ka hoʻoheheʻe ʻia ʻana, ʻoi aku ka maikaʻi o ka hoʻoponopono ʻana i ka pilikia o ke sila pākaukau.

ʻIkepili Mold

Alakaʻi Papahana: Zach

Mold Mold: Plastic injection mold, Stamping Die, Plastic Rubber Mould, Hot Chamber Die Casting, Foaming Mould, Press Tool Stamping Die Punch Die,

Ka manawa hoʻouna: 20-45 mau lā

Mold Material: NAK80, S136, 136H, 718H, P20, 718, 45 #, etc.

-

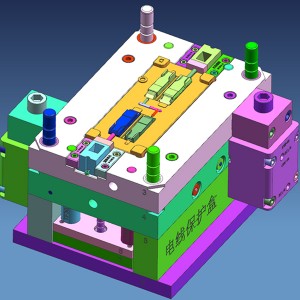

Pūnaehana pumehana hale kūʻai akamai Mold Development

He 15 mau makahiki o ka ʻike ʻana o UNI MOLDING i ka hoʻomohala ʻana i ka mold injection plastic, ʻoi aku hoʻi i ka mīkini ʻeleʻele shell mold, support frame mold, mechanical device plastic mold. I ke kaʻina o ka hoʻomohala mau ʻana, nui nā mea kūʻai aku e hoʻomaikaʻi nei i kā lākou huahana, mai ka hao hao a hiki i ke kaʻina stamping stainless steel, mai ka hana metala a hiki i ka hoʻoheheʻe ʻana i ka plastik. Ke hoʻomaikaʻi mau nei mākou i nā pilikia e pili ana i ka pale ʻana i ka corrosion, ke kūpaʻa wela kiʻekiʻe a me ka pale ʻana o UV o ka hoʻoheheʻe ʻana i ka plastic injection e hana i ka hana o nā huahana plastic i ʻoi aku ka maikaʻi ma mua o nā huahana kaʻina hana. I ka hoʻomohala wikiwiki ʻana i nā makahiki i hala iho nei, ua hoʻomohala mākou i ka pahu pahu wiliwili optical fiber; ʻO ka laina lalo o ka ʻāʻī ʻāʻī opipiula pale pale ʻili; Kākoʻo i ka hoʻoheheʻe ʻia o ke kahua kahua hoʻouna hōʻailona.

Māhele kikoʻīMāhele Māhele: ABS, PVC, PC, PP, BRASS, STAINLESS STEEL 304/316 Māhele Nui: 255 * 176 * 100 mm Māhele Kala: Kekahi kalaʻenehana nui a me nā kaʻina hanaNānā Mold → ʻoki ʻana i ka mīkini ʻoki → Drill hohonu → CNC Rough Machining → Heat Treating → Finishing Machining → Wire Cutting → EDM → Polishing → Texture → Mold Assembly and Debugging → Mold TestʻO ka mālama ʻana no ka hoʻomohala ʻana i ka ʻōnaehana hoʻoheheʻe papahele.

Māhele kikoʻīMāhele Māhele: ABS, PVC, PC, PP, BRASS, STAINLESS STEEL 304/316 Māhele Nui: 255 * 176 * 100 mm Māhele Kala: Kekahi kalaʻenehana nui a me nā kaʻina hanaNānā Mold → ʻoki ʻana i ka mīkini ʻoki → Drill hohonu → CNC Rough Machining → Heat Treating → Finishing Machining → Wire Cutting → EDM → Polishing → Texture → Mold Assembly and Debugging → Mold TestʻO ka mālama ʻana no ka hoʻomohala ʻana i ka ʻōnaehana hoʻoheheʻe papahele.- ʻO ka uhi hōʻailona e hana ʻia me ka acrylic high light transmittance material, i like ka hopena me ke kukui;

- Hoʻohana mākou i ka ʻike o ka ʻūhā ua hoʻoheheʻe ʻia no ka hoʻomaikaʻi ʻana i ka pū kani;

- I mea e hoʻoneʻe ai i ka wehe ʻana o ka alarm, hoʻohana mākou i ka hoʻoheheʻe ʻana i ka hoʻopili ʻana i ka magnet ikaika, a hoʻohana i ka huki ʻana o ka magnet e hoʻoponopono i ka alarm;

- Pono e noʻonoʻo pono ʻia ka hoʻohaʻahaʻa ʻana a me ka hoʻololi ʻana o nā ʻāpana plastik, ke kaua ʻana o nā ʻāpana hehi kila kila, ka hoʻomanawanui ʻana o nā papa kaapuni, a me ka hoʻolālā kaapuni kūloko o nā huahana alarm.

ʻIkepili MoldKa Papahana Papahana: Ken Mold Type: Plastic injection mold, Stamping Die, Plastic Rubber Mould, Hot Chamber Die Casting, Foaming Mould, Press Tool Stamping Die Punch Die, Delivery Time: 20-45 days Mold Material: NAK80, S136, 136H, 718H , P20, 718, 45#, etc.

ʻIkepili MoldKa Papahana Papahana: Ken Mold Type: Plastic injection mold, Stamping Die, Plastic Rubber Mould, Hot Chamber Die Casting, Foaming Mould, Press Tool Stamping Die Punch Die, Delivery Time: 20-45 days Mold Material: NAK80, S136, 136H, 718H , P20, 718, 45#, etc. -

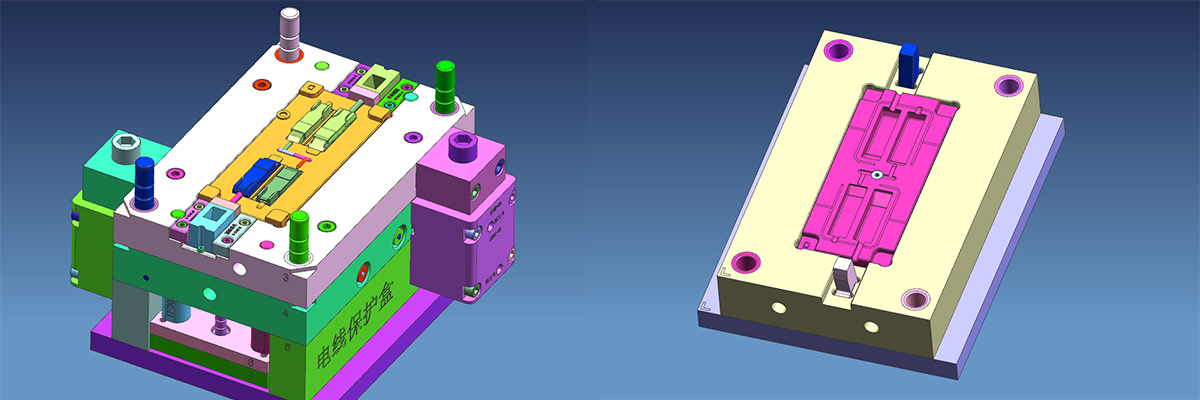

Mea Hana Injection Mold a me ka lawelawe hoʻoheheʻe ʻana no ka mākeke ʻAmelika no ka uhi Uila Plastic

Ua hana ʻo Uni Molding i ʻoi aku ma mua o 30 mau pūʻulu o nā pahu pahu pahu hui like ʻole, me kahi pūʻulu o ka optoelectronic pili i ka plastic mold, e like me ke kiʻekiʻe-voltage cable junction box mold, optical fiber junction box mold, mika shell mold, wire connection protection mold, etc. .

ʻOiai he liʻiliʻi ka uhi uwea ma kēia papahana, pono e noʻonoʻo ʻia nā kikoʻī he nui. No ka mea he huahana kēia i hoʻohana hou ʻia no nā manawa he nui, ma kahi o kona insulation, anti-aging, UV resistance, waterproof a me nā mea pili ʻē aʻe, pono e noʻonoʻo ʻia kona maʻalahi no ka hoʻohana hou ʻana.

Māhele kikoʻī

Māhele Māhele: PP + UV

Kala ʻāpana: ʻEleʻele

Kaumaha ʻāpana: 8g

ʻenehana nui a me nā kaʻina hana

Nānā Mold → ʻoki ʻana i ka mīkini ʻoki → Drill hohonu → CNC Rough Machining → Heat Treating → Finishing Machining → Wire Cutting → EDM → Polishing → Texture → Mold Assembly and Debugging → Mold Test

Nā Luʻi Nui a me nā Hoʻonā

C1: ʻO ka ʻelemakule o ka huahana plastik;

S1: E hana i ka ʻāpana kala i ʻeleʻele ʻeleʻele a hoʻohui i ka UV, hiki ke pale pono i ka wā kahiko a me UV.

C2: E hōʻoia i ka ʻāpana pono e pelu pinepine ʻia me ka haki ʻole a keʻokeʻo;

S2: E hoʻohana i ka PP no-silicon copolymerized ma ke ʻano he kumu kumu, a hoʻohui i kekahi mau mea kōkua kūpono e hoʻokō ai i ka hopena maikaʻi loa o ka PP (Maikaʻi piha piha, ikaika kiʻekiʻe, rigidity kiʻekiʻe, kūpaʻa wela maikaʻi, kūpaʻa maikaʻi, ʻoi aku ka paʻakikī haʻahaʻa haʻahaʻa. (ʻoluʻolu maikaʻi), ʻikea maikaʻi, a me ka nani o ka nani.)

ʻIkepili Mold

l Alakaʻi Papahana: Zach

l Mold Mold: PP plastic injection mold

l Hoʻouna manawa: 28 lā

l Nui Huahana: 10*6*3

l Nui Mold:400x280x360 mm

l Mold Cavity: 2 lua

l Mold Main Material: S136

l Mold Material: 718H, P20, 718, 45 #, etc.

l Mold Injection System: puka kiko

l Manawa Kaapuni Mold: 12”

-

Plastic Injection Shower Drain Mold Stamping Die Casting Mold

Ke holomua nei ka UNI MOLDING i ka hana ʻana i nā mole wai ʻauʻau kiʻekiʻe a ʻoi aku ka ʻenehana kiʻekiʻe i ka hoʻoheheʻe ʻia ʻana, ka hoʻoheheʻe ʻana, ka hoʻoheheʻe ʻilika me ka hopena hoʻoheheʻe. Ke holomua nei ka UNI MOLDING i ka hana ʻana i nā mole wai ʻauʻau kiʻekiʻe a ʻoi aku ka ʻenehana kiʻekiʻe i ka hoʻoheheʻe ʻia ʻana, ka hoʻoheheʻe ʻana, ka hoʻoheheʻe ʻilika me ka hopena hoʻoheheʻe.

Hāʻawi pū mākou i ka hoʻonā hana maʻamau no ka R&D a me ka hoʻolālā papahele ʻauʻau plastik a me ka hoʻomohala ʻana i ke kumu hoʻohālike hou me ka papaʻaina a me ka hoʻoheheʻe ʻana i ka hoʻonohonoho piha, ʻike ʻia ka hoʻolālā kiʻi kiʻi a pēlā aku. No laila, kaulana ʻo UNI MOLDING no kā mākou ʻenehana R&D i ka ʻōnaehana papa ʻauʻau a me kā mākou hoʻomohala ʻana i ke ʻano hoʻohālike.

Māhele kikoʻī

Mahele Mahele: ABS, PVC, PC, PP, BRASS, STAINLESS STEEL 304/316, BRASS, ZINK, ALUMINIUM

Nui o ka ʻāpana: 3.5 ʻīniha, 4 ʻīniha, 6 ʻīniha ka wai wai; 6/12/24/28/30/32/36/48 iniha laina laina

Kala ʻāpana: ʻO kēlā me kēia kala

ʻenehana nui a me nā kaʻina hana

Nānā Mold → ʻoki ʻana i ka mīkini ʻoki → Drill hohonu → CNC Rough Machining → Heat Treating → Finishing Machining → Wire Cutting → EDM → Polishing → Texture → Mold Assembly and Debugging → Mold Test

Hoʻoheheʻe i ka make, hoʻoheheʻe ʻia, hoʻoheheʻe ʻia i loko o ka ipu hao, ʻeleʻele Rubber Mould, Hoʻoheheʻe ʻia ʻo ke keʻena wela, hoʻolei ʻia ke one, hoʻoheheʻe ʻia, hoʻoheheʻe ʻana, mea paʻi paʻi ʻana i nā mea hoʻoheheʻe make Punch Die.

ʻO ka mālama ʻana no ka hoʻomohala ʻana i ka ʻōnaehana hoʻoheheʻe papahele.

- E hoʻolālā i kahi pali e hoʻomaʻemaʻe i ka wai;

- Pono e noʻonoʻo ʻia nā ana a me nā mea o nā paipu hoʻoheheʻe ma nā ʻāina like ʻole a me nā ʻāina;

- Kāohi i ke kila kuhiliʻole 304 mai ka ʻeleʻele a me ka papa electroplating mai ka hāʻule ʻana;

- ʻO ka hoʻololi ʻana i ke kihi kiʻekiʻe i ka wā e hoʻokomo ai;

- Hoʻopiha i ka palapala hōʻoia a me nā mea kūpono e hōʻoia i ka hōʻoia kūpono;

ʻIkepili Mold

Alakaʻi Papahana: Zach

Mold Mold: Mold injection mold, Stamping Die, Casting Mold, Plastic Rubber Mould, Hot Chamber Die Casting, Sand Mold Casting, Compression Molding, Foaming Mould, Press Tool Stamping Die Punch Die,

Ka manawa hoʻouna: 20-45 mau lā

Mold Material: NAK80, S136, 136H, 718H, P20, 718, 45 #, etc.

-

Paʻa ʻauʻau ʻauʻau ABS ABS

He huahana hale palaki kēia i hoʻohana ʻia i ke ʻano o ka hoʻoheheʻe wai a me ka wai wai. No ka mea, ʻo nā hale ma ka mākeke ʻAmelika ʻĀkau he mau hale lāʻau a pau, inā ʻaʻole maikaʻi ka wai ʻauʻau o ka hale ʻauʻau, e kū ana ia i ka pulupulu, palaho, nā nalo a me nā mea pili i ka hale. No laila, hiki i ka hoʻomohala ʻana o ka pā ʻauʻau ʻauʻau a me ka hana ʻana i ka pā wai wai wai hiki ke kōkua i ka poʻe e hoʻoponopono i nā pilikia. Māhele kikoʻī Māhele Māhele: ABS + 15% GF Nui ʻāpana: 60×48 iniha... -

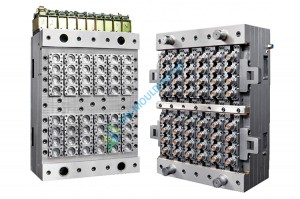

Pehea e pili ana i ka Multi Cavity Injection Molds Making

E like me ka nui o ka mana hana, ka hoʻolālā huahana. Hoʻoholo ia i ka helu kūpono o nā cavities, ʻoi aku ka pololei o nā mold, ka paʻakikī o ka hana. ʻO ke kiʻekiʻe o ke kumukūʻai o ka lua mold. Eia naʻe, ua emi nui ke kumukūʻai o nā ʻāpana i hoʻoheheʻe ʻia.

-

ABS extruded profile

Hoʻohana nui ʻia ʻo ABS extrusion strip i nā mea kūkulu hale, ka puka puka, ke kiʻi hoʻonaninani a me ke kiʻi kiʻi. He ikaika maikaʻi ko ABS extruded frame, paʻakikī a me ka pale ʻana i ka corrosion, a loaʻa ka hoʻokūkū mākeke maikaʻi i ke kumukūʻai. I nā makahiki he nui o ka noiʻi, hoʻomohala ʻana a me ka hoʻāʻo ʻana o kā mākou hui, ʻoi aku ka maikaʻi o kā mākou kime ABS extruded i hana ʻia ma mua o kāna mau hoa ma ka mākeke ma ka ikaika, ka paʻakikī, ka pale ʻana i ka corrosion a me nā aesthetics. Ua hana nui ia i ka mākeke ʻEulopa a ua hoʻohana nui ʻia i ka hoʻonaninani hale ʻEulopa.

-

Poʻo ʻOmole ʻOihana

Hana kūikawā ʻo Uni-Moulding i ka hāʻawi ʻana i nā ʻano like ʻole o nā ʻano pahu pahu. Loaʻa iā mākou ka hui R&D piha, ke keʻena hoʻolālā, nā lako hana hoʻoponopono kiʻekiʻe, ke keʻena nānā maikaʻi a me ka hui lawelawe ma hope o ke kūʻai aku e hōʻoia i ka maikaʻi maikaʻi o kēlā me kēia pālua. Me nā makahiki he 15 o ka ʻike waiwai, ua hana mākou i nā ʻano pāpale he nui, e like me nā pāpale flip-top, nā pāpale bow-knot, nā pāpale ʻelima galani, nā pāpale hoʻonaninani, a me nā mea ʻē aʻe (a hiki i 128 cavities). Loaʻa i kā mākou mau ʻōmole pāpale ʻōmole nā mea maikaʻi.

-

Paʻi 3D

Me ka hoʻomohala a me ke oʻo ʻana o ka ʻenehana paʻi 3D, ua hoʻohana ʻia ka ʻenehana paʻi 3D i nā manawa he nui i ka hoʻolālā huahana a me ka noi ʻana o Uni-Molding. Hoʻohana nui ia i ka lāʻau lapaʻau, nā haʻuki a me nā mea kūkulu hale. ʻO nā papa kolepa i loko, nā mea hoʻopaneʻe baseball, nā mea hoʻonani o ka moe, nā bearings ʻoihana, nā ipu ana, nā lima puka a me nā puka makani, nā mahiole, nā pale pale, etc.

Eia nō naʻe, loaʻa i ka paʻi 3D kekahi mau palena ʻenehana. -

Noho Keena Hope

Kumu Mold: DME

Mold Material: S136 Heat Treated

Māhele Māhele: TPU