-

Liquid Silicone Txhaj Molding Services

Silica gel tau siv dav hauv kev ua lag luam vim nws tsis tso cov tshuaj lom, muaj qhov muag muag thiab xis nyob, thiab muaj lub cev zoo thiab tshuaj lom neeg ntawm qhov kub thiab txias (-60c ~ + 300c). Muaj ob peb lwm cov polymers uas tuaj yeem phim nws.

Muaj zog elastomer, zoo dua li cov roj hmab sealing, zoo heev hluav taws xob rwb thaiv tsev, thiab tiv thaiv cov tshuaj, fuels, roj, thiab dej, ib tug zoo cov ntaub ntawv los tiv thaiv tej yam tsis zoo.

Hauv kev lag luam, xws li roj foob, cov yuam sij keyboard, cov khoom siv hluav taws xob rwb thaiv tsev, cov khoom siv hauv tsheb, cov khoom siv niaj hnub xws li pacifiers, catheters dag, lub tshuab ua pa, qag iav, tawv khau thiab khau ntaub, ntim khoom noj, thiab lwm yam.

Yog tias koj muaj qee qhov sliicone xav tau kev tsim khoom, tsuas yog hu rau peb kom tau txais kev paub ntau ntxiv.

Dab tsi yog qhov sib txawv ntawm cov kua silica gel thiab cov khoom silica gel?

Silicone kua

Liquid silica gel yog ib hom khoom kub-kub vulcanized silicone roj hmab. Nws yog cov kua gel nrog zoo fluidity, ceev vulcanization, kev nyab xeeb thiab kev tiv thaiv ib puag ncig, thiab tuaj yeem ua tau raws li cov kev cai ntawm qib zaub mov.

Khoom siv silica gel

Cov khoom siv silica gel yog ib yam khoom siv saturated polymer elastic, uas muaj cov yam ntxwv ntawm qhov kub thiab txias, tiv taus txias, hnyav ua haujlwm, tiv thaiv kev tiv thaiv, tiv thaiv nplaum, hluav taws xob rwb thaiv tsev, tshuaj tiv thaiv thiab muaj ntau yam kev thov.

1. Cov kua silica gel thiab cov khoom zoo li qub

(1) Raws li lub npe implies, kua silica gel yog kua thiab muaj liquidity

(2) Cov khoom silica gel yog khoom, tsis muaj kuab lom!

2. Kev siv cov kua silica gel thiab cov khoom silica gel

(1) Cov kua silica gel feem ntau yog siv rau hauv cov khoom me me, cov khoom siv hauv chav ua noj, thiab cov khoom siv kho mob, uas tuaj yeem tiv tauj cov zaub mov thiab tib neeg lub cev.

(2) Cov khoom siv silica gel feem ntau yog siv rau hauv cov khoom siv niaj hnub thiab cov khoom lag luam thiab cov khoom pib, thiab lwm yam., daim ntawv thov ntau yam kuj dav.

3. Kev nyab xeeb ntawm cov khoom silica gel thiab kua silica gel

(1) Cov kua silica gel yog cov pob tshab thiab cov khoom noj khoom haus muaj kev nyab xeeb siab, molding tsis ntxiv vulcanizing tus neeg saib xyuas thiab lwm yam khoom siv pabcuam, ntim khoom noj molding.

(2) Cov khoom siv silica gel yog cov khoom siv tiv thaiv ib puag ncig pob tshab, kev tsim cov khoom yuav tsum tau ntxiv tus neeg saib xyuas kom ua kom lub sijhawm kho kom zoo, thiab qhib pwm pub molding.

4. Ua kua silica gel thiab khoom silica gel molding txoj kev

(1) Cov kua silicone yog txhaj tshuaj molding kua silicone roj hmab (LSR): tag nrho lub npe rau kev txhaj tshuaj molding kua silicone roj hmab, kho cov cuab yeej rau kev txhaj tshuaj molding tshuab.

Kev txhaj tshuaj molding tshuab muaj cov txheej txheem thev naus laus zis uas yooj yim heev, tsis tas yuav yog cov txheej txheem ntawm cov khoom siv kua nplaum kub kub, sib tov, blanking, cov khoom siv thiab cov txheej txheem, tsuas yog ib tus neeg ua haujlwm coj cov khoom), cov khoom lag luam siab (hmoov molding ua ntej tag nrho. phau ntawv kev pab cuam yuav hloov los ntawm A tshuab), siab tso zis (A / B kua nplaum sib tov, nyob rau hauv ib tug tej yam kub rau ib tug ob peb vib nas this kom zoo), txuag, txuag hluav taws xob, txuag cov ntaub ntawv thiab lwm yam zoo, muaj peev xwm tsim tag nrho cov kub-kub kua nplaum. cov khoom tsim tawm! Nws yog ib qho tseem ceeb ntawm silicone roj hmab cov ntaub ntawv kev loj hlob nyob rau hauv ob peb xyoos tom ntej no.

(2) Cov khoom siv silica gel molding yog cov khoom siv raw uas yog ib qho ntawm cov khoom, los ntawm kev sib xyaw tshuab sib xyaw, lub tshuab txiav yog txiav rau hauv cov khoom thiab txhaj pwm qhov tsim nyog loj thiab tuab, thiab tom qab ntawd mus rau hauv pwm, siab molding tshuab hauv qab. ib qho kub molding. Demoulding thiab cov khoom yas txog tib yam, kuj yuav tsum tau ntxuav cov pwm.

5. Cov khoom ua kua silica gel thiab cov khoom siv silica gel yuav ua li cas kom paub qhov txawv

Cov kua silica gel pob tshab yog siab, tsis muaj ntxhiab tsw, thiab cov khoom muaj lub qhov ncauj txhaj tshuaj kua nplaum. Khoom ntxhib pore silica gel pob tshab hauv qab, vulcanizing tus neeg saib xyuas lossis lwm lub npog vulcanizing tus neeg sawv cev tshuaj tsw qab, ib yam khoom tsis muaj qhov ncauj txhaj

-

Tee Joint & P-Trap Pwm Ua thiab Txhaj Moulding Ntau Lawm

Tee sib koom tes thiab lub luj tshib tau siv dav hauv cov kav dej ua kua, cov kav dej cua thiab cov khoom siv kho mob, Nws muaj ntau yam sib txawv, qhov ntev, thiab cov qauv.

Rau kev sib koom tes tee zoo tib yam, cov qauv yog yooj yim heev, tab sis rau ntau lub teb chaws thiab kev lag luam, qhov sib xws thiab cov kev siv tau sib txawv.

Txawm li cas los xij, nyob rau hauv kev xav txog cov teeb meem ntawm cov kua thiab tsw qab, ib tug complex qauv yog ua tiav nyob rau hauv lub hauv paus ntawm ib txheej ntawm pwm, uas tseem yuav tsum tau txaus kev paub nyob rau hauv tsim thiab ntau lawm.

Hauv peb ze li tsib xyoos ntawm txoj kev loj hlob, peb tau sau ntau tshaj 80 hom tee thiab yeeb nkab haum cov khoom pwm kev tsim kho.

Zoo li Asmeskas tus qauv ABS thiab PVC cov yeeb nkab pov tseg, nws suav nrog kev tsim khoom ntawm ABS / PVC tee pwm thiab tee txhaj molding ntawm ntau qhov ntau thiab tsawg xws li 1 nti, 1.5 nti, 2 nti, thiab 3 nti. Peb kuj muaj qee qhov kev tsim khoom rau PPR tee pwm rau peb cov neeg siv khoom South Africa (Yuav kom pab cov neeg siv khoom txuag cov nqi tsim pwm, raws li peb cov pwm pwm, peb paub txog cov khoom ntawm 12 tee qhov chaw los ntawm kev hloov pwm core thiab inserts) . Qhov nyuaj tshaj plaws yog peb txoj kev tsim pwm thiab cov khoom tsim khoom ntawm cov khoom siv kho mob me me thiab tsis siv neeg txau.

Nqe lus piav qhia

Cov khoom siv: ABS, PVC, PPR, PP, PC

Xim Xim: Txhua xim

Main Technology thiab Txheej Txheem

Mould Analysis → Sawing Tshuab Txiav → Qhov tob Drill → CNC Rough Machining → Thaum tshav kub kub kho → Finishing Machining → Hlau txiav → EDM → Polishing → Texture → Pwm los ua ke thiab Debugging → Mould Test

Main Mould Development Experience

P Trap Pwm, Tee PVC Fitting Connector (1/2", 3/4", 1", 1-1/4", 1-1/2", 2", 3"), 2 in. Glueless Soundproof DWV Sanitary Tee, 2 in. DWV PVC P-Trap with Solvent Weld Joint, 2" Plain 90 Degree PVC Tee

Pwm Paub meej

Project Leader: Zach

Pwm Hom: Yas Txhaj Mould

Lub sij hawm xa tuaj: 20-45 hnub

Pwm Khoom: NAK80, S136, 136H, 718H, P20, 718, 45 #, thiab lwm yam.

-

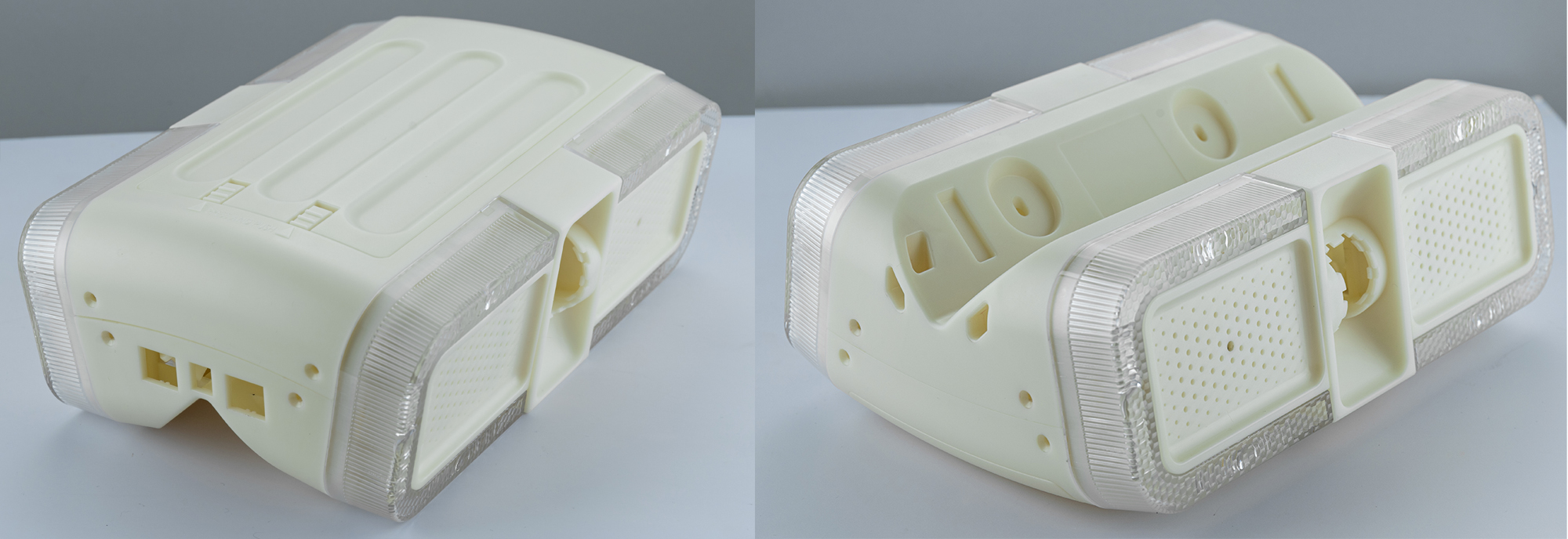

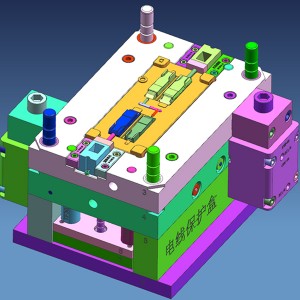

Roj teeb Case Pwm Txhim Kho thiab ABS Roj Teeb Plhaub Txhaj Tshuaj Molding Services

Roj teeb teeb peb tau siv dav hauv kev lag luam tsheb thiab maus taus, Nws muaj ntau yam qauv thiab qhov ntev.

Thaum lub sij hawm 9 xyoo, Uni Molding tau tsim ntau tshaj 50 teev roj teeb rooj plaub pwm thiab ntau yam roj teeb rooj pwm. Nyob rau hauv cov ntaub ntawv roj teeb pwm kev loj hlob feem ntau yog hais txog cov kub khiav txhaj tshuaj pwm ntawm lub roj teeb rooj plaub, lub puab pwm ntawm lub roj teeb rooj npog, thiab stamping pwm ntawm tooj liab qhov chaw.

Nyob rau hauv tus txheej txheem ntawm kev koom tes ntau lawm, peb niaj hnub kawm txog kev ua haujlwm ntawm lub roj teeb thiab kev ceev faj rau kev sib sau ua ke ntawm Circuit Board. Ntxiv nrog rau kev daws teeb meem ntawm lub roj teeb plhaub pwm kev txhim kho, nws tseem tuaj yeem pab cov roj teeb sib dhos thiab kuaj.

Nqe lus piav qhia

Khoom siv: ABS, tooj dag

Sab hauv Loj: 106 × 63 × 61 mm; 143 × 79.5 × 73.5 mm; 145 × 64 × 111 hli; 144 × 80 × 110 hli; 107 × 68 × 82 hli; 105 × 52 × 68 hli; 105 × 26 × 69 hli; 105 × 68 × 108 hli;

Xim Xim: Txhua xim

Main Technology thiab Txheej TxheemMould Analysis → Sawing Tshuab Txiav → Qhov tob Drill → CNC Rough Machining → Thaum tshav kub kub kho → Finishing Machining → Hlau txiav → EDM → Polishing → Texture → Pwm los ua ke thiab Debugging → Mould Test

Kev ceev faj rau kev tsim cov dej hauv pem teb.

Hauv kev txhaj tshuaj molding ntawm roj teeb rooj pwm, qhov teeb meem ntawm cov khoom nto shrinkage thiab kev sib koom tes yog daws tau;

Siv nplaim retardant ABS los hloov ABS zoo tib yam rau kev txhaj tshuaj molding;

Lub tooj dag stamping electrode yog chrome plated thiab tom qab ntawd ABS hla kev txhaj tshuaj molding, uas zoo dua daws cov teeb meem ntawm roj teeb foob.

Pwm Paub meej

Project Leader: Zach

Pwm Hom: Yas Txhaj Mould, Stamping Tuag, Yas Roj Hmab Pwm, Kub Chamber Tuag Casting, Foaming Pwm, Xovxwm Tool Stamping Tuag Punch Tuag,

Lub sij hawm xa tuaj: 20-45 hnub

Pwm Khoom: NAK80, S136, 136H, 718H, P20, 718, 45 #, thiab lwm yam.

-

Intelligent warehouse tswb system Mould Development

UNI MOLDING muaj 15 xyoo dhau los ntawm kev tsim cov yas txhaj tshuaj pwm, tshwj xeeb tshaj yog nyob rau hauv cov khoom siv hluav taws xob plhaub pwm, txhawb pwm pwm, cov cuab yeej siv tshuab yas pwm. Nyob rau hauv tus txheej txheem ntawm kev txhim kho tas mus li, ntau tus neeg muas zaub tau kho lawv cov khoom, los ntawm cam khwb cia hlau mus rau stainless hlau stamping txheej txheem, los ntawm hlau ua rau yas txhaj molding. Peb niaj hnub txhim kho cov teeb meem cuam tshuam txog kev tiv thaiv corrosion, kub tsis kam thiab UV tsis kam ntawm cov yas txhaj tshuaj molding kom ua tau zoo ntawm cov khoom yas zoo dua li lwm cov txheej txheem khoom. Nyob rau hauv txoj kev loj hlob sai nyob rau hauv xyoo tas los no, peb tau tsim cov yas optical fiber ntau winding lub thawv pwm; Hauv qab kab optical cable ncej tiv thaiv plhaub pwm; Txhawb pwm ntawm cov teeb liab kis tau tus mob hauv paus chaw nres tsheb.

Nqe lus piav qhiaCov khoom siv: ABS, PVC, PC, PP, BRASS, STAINLESS STEEL 304/316 Qhov Loj: 255 * 176 * 100 mm Xim Xim: Txhua ximMain Technology thiab Txheej TxheemMould Analysis → Sawing Tshuab Txiav → Qhov tob Drill → CNC Rough Machining → Thaum tshav kub kub kho → Finishing Machining → Hlau txiav → EDM → Polishing → Texture → Pwm los ua ke thiab Debugging → Mould TestKev ceev faj rau kev tsim cov dej hauv pem teb.

Nqe lus piav qhiaCov khoom siv: ABS, PVC, PC, PP, BRASS, STAINLESS STEEL 304/316 Qhov Loj: 255 * 176 * 100 mm Xim Xim: Txhua ximMain Technology thiab Txheej TxheemMould Analysis → Sawing Tshuab Txiav → Qhov tob Drill → CNC Rough Machining → Thaum tshav kub kub kho → Finishing Machining → Hlau txiav → EDM → Polishing → Texture → Pwm los ua ke thiab Debugging → Mould TestKev ceev faj rau kev tsim cov dej hauv pem teb.- Cov teeb liab npog yuav tsum yog ua los ntawm acrylic high light transmittance khoom, uas yuav tsum muaj cov nyhuv tib yam li lub teeb;

- Peb siv cov kev paub ntawm nag da dej pwm rau siv los txhim kho lub suab horn;

- Txhawm rau txav lub tswb nrov ntawm lub tswb, peb siv cov tshuaj molding los qhwv cov hlau nplaum muaj zog, thiab siv qhov kev nyiam ntawm cov hlau nplaum los kho lub tswb;

- Shrinkage thiab deformation ntawm yas qhov chaw, warpage ntawm stainless hlau stamping qhov chaw, qhov ntev kam rau ntawm Circuit Court boards, thiab sab hauv Circuit Court kev npaj ntawm lub tswb yuav tsum tau muab xam.

Pwm Paub meejTus Thawj Coj Ua Haujlwm: Ken Pwm Hom: Yas Txhaj Pwm, Stamping Tuag, Yas Roj Hmab Mould, Kub Chamber Tuag Casting, Foaming Pwm, Xovxwm Tshuab Stamping Tuag Punch Tuag, Lub Sij Hawm Lub Sij Hawm: 20-45 hnub Pwm Khoom siv: NAK80, S136, 136H, 718H , P20, 718, 45#, thiab lwm yam.

Pwm Paub meejTus Thawj Coj Ua Haujlwm: Ken Pwm Hom: Yas Txhaj Pwm, Stamping Tuag, Yas Roj Hmab Mould, Kub Chamber Tuag Casting, Foaming Pwm, Xovxwm Tshuab Stamping Tuag Punch Tuag, Lub Sij Hawm Lub Sij Hawm: 20-45 hnub Pwm Khoom siv: NAK80, S136, 136H, 718H , P20, 718, 45#, thiab lwm yam. -

Yas Txhaj Mould Maker thiab Txhaj Moulding Kev Pabcuam rau Tebchaws USA Kev Lag Luam rau Yas Cable Npog

Uni Moulding tau ua ntau tshaj 30 teeb ntawm ntau yam hlws ris lub thawv pwm, nrog rau cov khoom siv ntawm optoelectronic ntsig txog yas pwm, xws li high-voltage cable hlws ris lub thawv pwm, optical fiber hlws ris lub thawv pwm, meter plhaub pwm, hlau txuas tiv thaiv pwm, thiab lwm yam. . peb muaj ntau yam kev paub nyob rau hauv junction box pwm manufacturing.

Txawm hais tias lub npog cable hauv qhov project no me me, ntau cov ntsiab lus yuav tsum tau xav txog. Vim tias qhov no yog cov khoom siv rov qab siv ntau zaus, ntxiv rau nws cov rwb thaiv tsev, tiv thaiv kev laus, UV tsis kam, tsis muaj dej tsis zoo thiab lwm yam khoom siv, nws qhov yooj yim rau rov siv dua yuav tsum xav txog.

Nqe lus piav qhia

Khoom siv: PP + UV

Xim Xim: Dub

Qhov hnyav: 8g

Main Technology thiab Txheej Txheem

Mould Analysis → Sawing Tshuab Txiav → Qhov tob Drill → CNC Rough Machining → Thaum tshav kub kub kho → Finishing Machining → Hlau txiav → EDM → Polishing → Texture → Pwm los ua ke thiab Debugging → Mould Test

Cov Kev Sib Tw Tseem Ceeb & Kev daws teeb meem

C1: Kev laus ntawm cov khoom yas;

S1: Ua ib feem xim rau xim dub thiab ntxiv UV, uas tuaj yeem tiv taus kev laus thiab UV.

C2: xyuas kom meej tias qhov yuav tsum tau muab tais ntau zaus tsis tawg thiab tig dawb;

S2: Siv tsis muaj-silicon copolymerized PP raws li cov khoom siv yooj yim, thiab ntxiv qee cov ntaub ntawv pabcuam tsim nyog kom ua tiav cov txiaj ntsig zoo tshaj plaws ntawm PP (Kev ua haujlwm zoo, siab zog, siab nruj, zoo tshav kub tsis kam, zoo seem stability, zoo heev low-temperature toughness. (zoo yoog tau), zoo pob tshab, thiab zoo glossiness.)

Pwm Paub meej

l Project Leader: Zach

l Pwm Hom: PP yas txhaj pwm

l Lub sij hawm xa tuaj: 28 hnub

l Khoom Loj: 10 * 6 * 3

l Pwm Loj: 400x280x360 mm

l Pwm Cavity: 2 kab noj hniav

l Pwm Main Khoom: S136

l Pwm Khoom: 718H, P20, 718, 45 #, thiab lwm yam.

l Pwm Txhaj System: Point gate

l Pwm lub sij hawm: 12 "

-

Yas Txhaj Da Dej Da Dej Pwm Stamping Tuag Casting Pwm

UNI MOLDING yog qib siab hauv kev ua kom zoo nkauj da dej pwm thiab tshwj xeeb tshaj yog cov cuab yeej siv siab stamping pwm, casting pwm, yas txhaj tshuaj pwm nrog tshaj molding tov. UNI MOLDING yog qib siab hauv kev ua kom zoo nkauj da dej pwm thiab tshwj xeeb tshaj yog cov cuab yeej siv siab stamping pwm, casting pwm, yas txhaj tshuaj pwm nrog tshaj molding tov.

Peb kuj muab kev cai tsim kev daws teeb meem rau R & D thiab yas da dej hauv pem teb tsim thiab tsim qauv tshiab nrog lub rooj thiab ntws hauv cov txheej txheem tag nrho, cov duab kos duab pom zoo thiab lwm yam. Yog li ntawd, UNI MOLDING yog nto moo rau peb R & D tehnology nyob rau hauv da dej pem teb system pwm thiab peb innovation yas qauv tsim.

Nqe lus piav qhia

Khoom siv: ABS, PVC, PC, PP, BRASS, STAINLESS STEEL 304/316, BRASS, ZINK, ALUMINIUM

Qhov Loj: 3.5 nti, 4 nti, 6 nti da dej ntws; 6/12/24/28/30/32/36/48 nti linear ntws

Xim Xim: Txhua xim

Main Technology thiab Txheej Txheem

Mould Analysis → Sawing Tshuab Txiav → Qhov tob Drill → CNC Rough Machining → Thaum tshav kub kub kho → Finishing Machining → Hlau txiav → EDM → Polishing → Texture → Pwm los ua ke thiab Debugging → Mould Test

Stamping Tuag, Casting Pwm, Yas Roj Hmab Pwm, Kub Chamber Tuag Casting, Sand Pwm Casting, Compression Molding, Foaming Pwm, Xovxwm Tshuab Stamping Tuag Punch Tuag

Kev ceev faj rau kev tsim cov dej hauv pem teb.

- Tsim ib qho kev nqes hav los pab kom cov dej ntws;

- Qhov ntev thiab cov khoom siv ntawm cov kav dej hauv ntau lub teb chaws thiab cheeb tsam yuav tsum raug txiav txim siab;

- Tiv thaiv stainless hlau 304 los ntawm xeb thiab electroplating txheej los ntawm ntog;

- Qhov siab lub kaum sab xis hloov thaum lub sij hawm installation;

- Ua kom tiav cov ntaub ntawv pov thawj thiab cov ntaub ntawv tsim nyog los xyuas kom meej cov ntaub ntawv pov thawj;

Pwm Paub meej

Project Leader: Zach

Pwm Hom: Yas Txhaj Mould, Stamping Tuag, Casting Pwm, Yas Roj Hmab Pwm, Kub Chamber Tuag Casting, Sand Pwm Casting, Compression Molding, Foaming Pwm, Xovxwm Tshuab Stamping Tuag Punch Tuag,

Lub sij hawm xa tuaj: 20-45 hnub

Pwm Khoom: NAK80, S136, 136H, 718H, P20, 718, 45 #, thiab lwm yam.

-

Yas ABS Waterproof Da Dej Pan Pwm

Qhov no yog cov khoom siv hauv tsev yas siv rau kev tsim kho vaj tsev ntawm chav dej thiab cov dej tsis zoo. Vim hais tias cov tsev nyob rau hauv North American lag luam yog tag nrho cov ntoo thav duab, thaum lub chav da dej tsis zoo waterproof, nws yuav fim mildew, lwj, termites thiab lwm yam teeb meem nyob rau hauv lub tsev. Yog li ntawd, txoj kev loj hlob ntawm tus da dej yias pwm thiab kev tsim cov yas da dej da dej tuaj yeem pab cov neeg daws teeb meem. Cov Lus Qhia Cov Khoom Siv: ABS + 15% GF Qhov Loj: 60 × 48 nti ... -

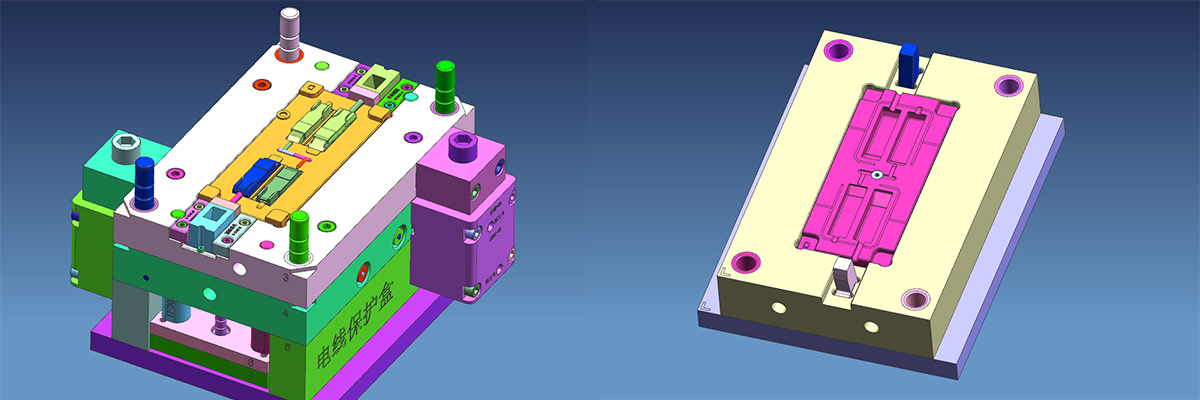

Yuav ua li cas txog Multi Cavity Txhaj Moulds Ua

Multi kab noj hniav pwm yog raws li qhov loj ntawm lub peev xwm ntau lawm, cov qauv khoom. Nws txiav txim siab qhov tsim nyog tus naj npawb ntawm kab noj hniav, ntau precision pwm, ua nyuaj. Qhov siab dua tus nqi ntawm cov pwm kab noj hniav. Txawm li cas los xij, tus nqi ntawm kev txhaj tshuaj molded qhov chaw poob qis heev.

-

ABS extruded profile

ABS extrusion sawb yog dav siv hauv cov khoom siv hauv tsev, qhov rooj ncej, kho kom zoo nkauj ncej thiab duab ncej. ABS extruded ncej muaj lub zog zoo, toughness thiab corrosion kuj, thiab muaj kev lag luam zoo sib tw ntawm tus nqi. Hauv ntau xyoo ntawm kev tshawb fawb, kev loj hlob thiab kev sim ntawm peb lub tuam txhab, peb tus kheej tsim ABS extruded ncej yog superior rau nws cov phooj ywg nyob rau hauv kev ua lag luam nyob rau hauv lub zog, toughness, corrosion kuj thiab zoo nkauj. Nws tau ua ib qho zoo heev hauv kev ua lag luam nyob sab Europe thiab tau siv dav hauv European tsev kho kom zoo nkauj.

-

Professional Lub raj mis Cap Pwm

Uni-Moulding tshwj xeeb hauv kev muab ntau hom lub raj mis hau pwm. Peb muaj ua tiav R & D pab neeg, tsim department, high-precision ua khoom, zoo soj ntsuam department thiab tom qab-muag pab pawg neeg los xyuas kom meej qhov zoo tshaj plaws ntawm txhua khub pwm. Nrog 15 xyoo ntawm kev nplua nuj, peb tau ua ntau hom kaus mom, xws li flip-top caps, hneev-knot caps, tsib-gallon caps, cosmetic caps, thiab lwm yam. (txog 128 kab noj hniav). Peb lub raj mis cap pwm muaj cov nram qab no zoo.

-

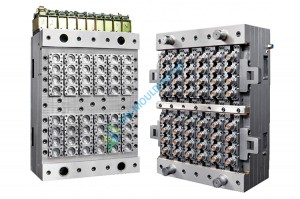

3D Luam Ntawv

Nrog rau kev txhim kho thiab kev loj hlob ntawm 3D tshuab luam ntawv, 3D tshuab luam ntawv tau siv ntau zaus hauv cov khoom tsim thiab kev siv ntawm Uni-Molding. Nws yog dav siv hauv kev kho mob, kev ua kis las thiab cov khoom siv hauv tsev. Cov chav kawm golf sab hauv tsev, cov khoom siv ntaus pob ncaws pob, cov khoom siv hauv txaj, kho kom zoo nkauj hauv txaj, muaj cov kabmob, ntsuas cov thawv, qhov rooj thiab qhov rais, cov kaus mom hlau, cov npog ntsej muag, thiab lwm yam.

Txawm li cas los xij, 3D luam ntawv tseem muaj qee qhov kev txwv. -

Office Chair Rov qab

Pwm Base: DME

Pwm Khoom: S136 Thaum tshav kub kub kho

Khoom siv: TPU