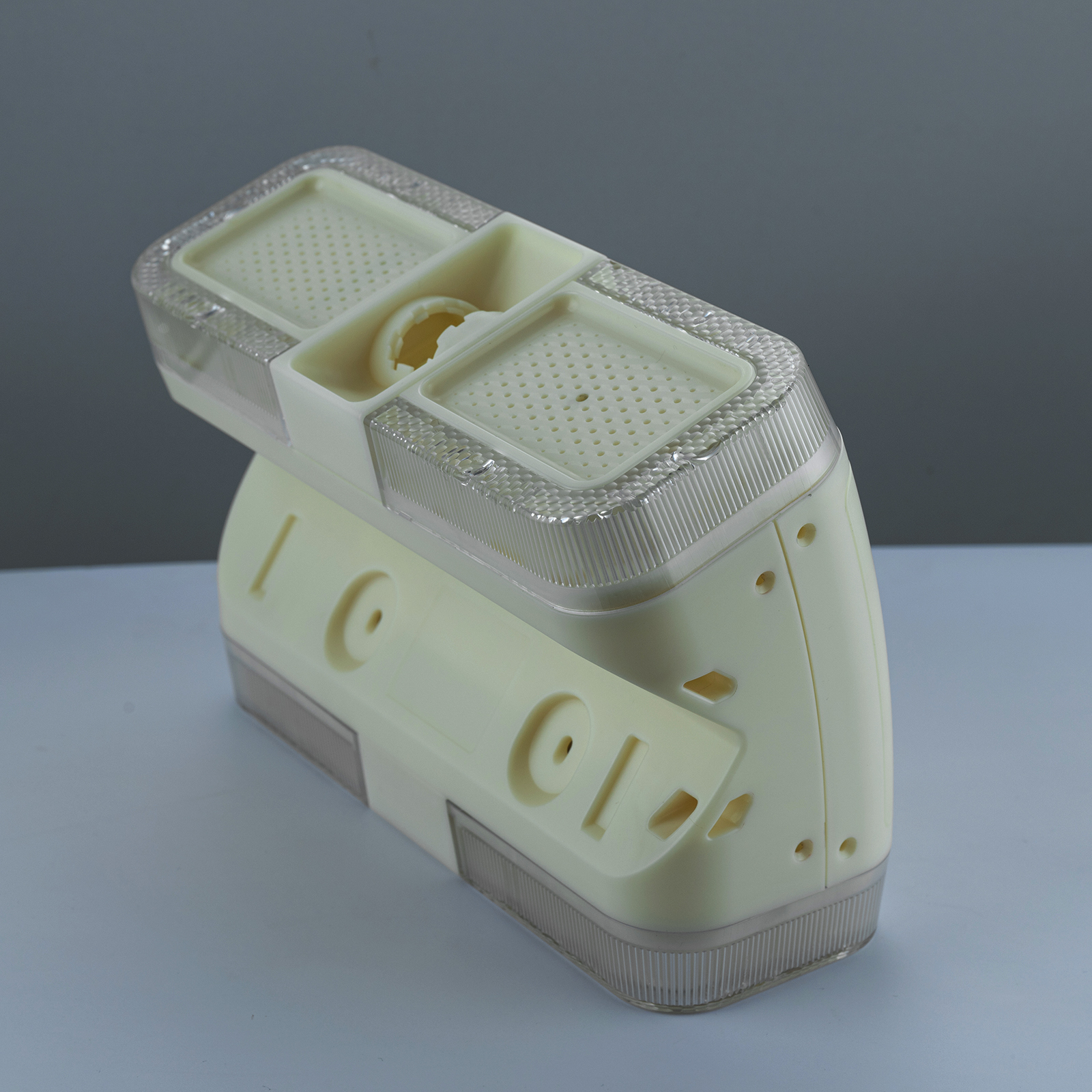

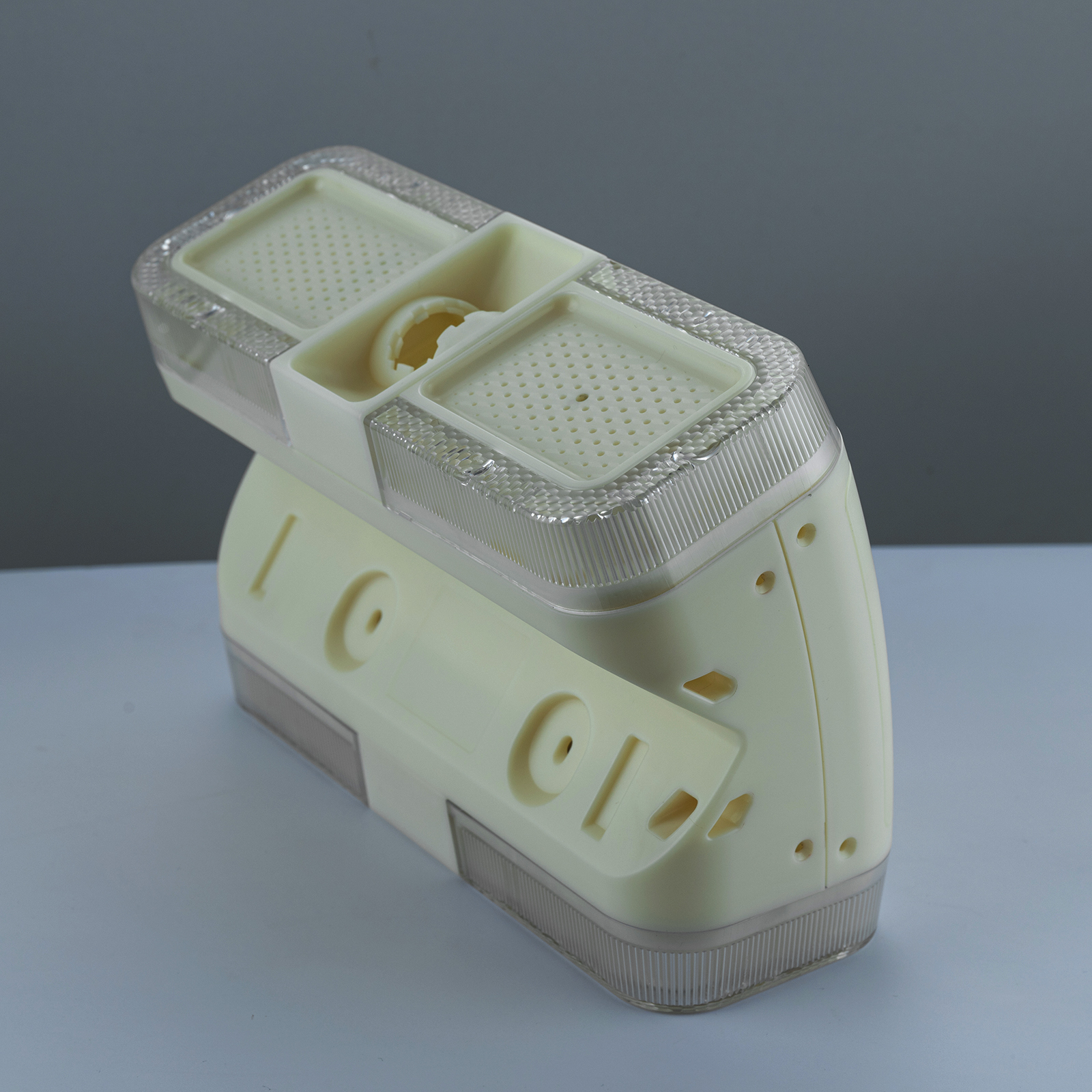

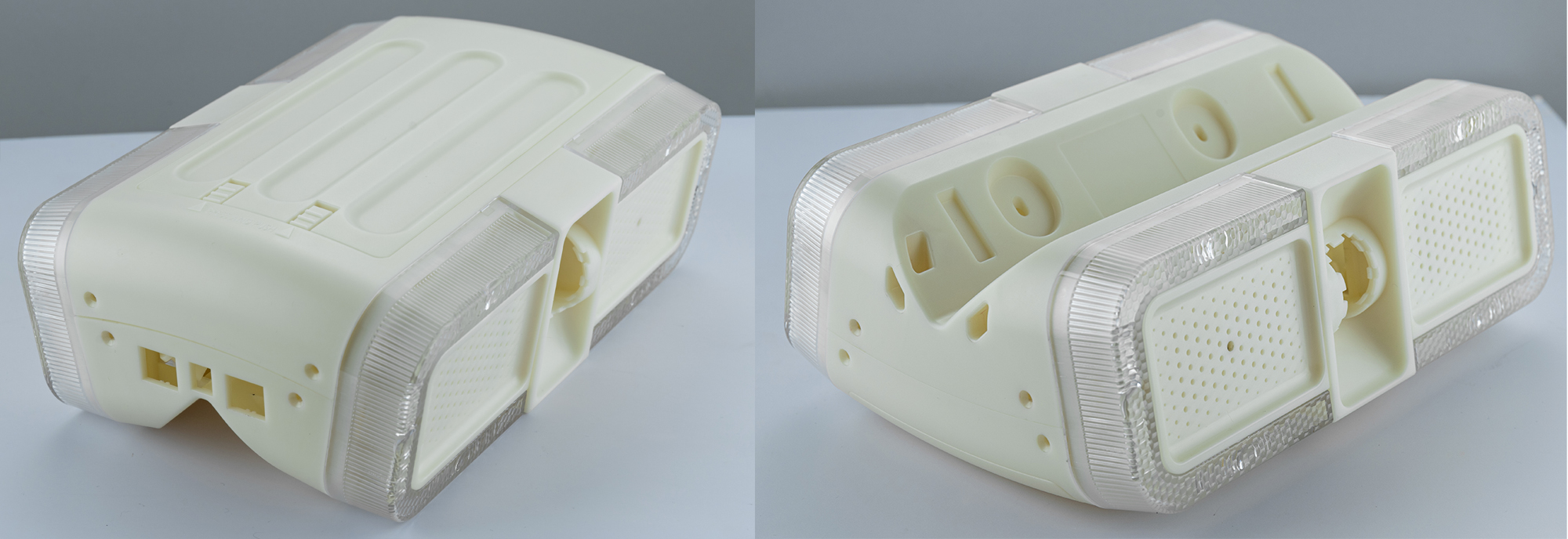

UNI MOULDING has 15 years of experience in plastic injection mold development, especially in electronic equipment shell mold, support frame mold, mechanical device plastic mold. In the process of continuous development, many customers have been upgrading their products, from cast iron to stainless steel stamping process, from metal processing to plastic injection molding. We are constantly upgrading the problems related to corrosion resistance, high temperature resistance and UV resistance of plastic injection molding to make the performance of plastic products better than other process products. In the rapid development in recent years, we have developed plastic optical fiber winding box mold; Bottom line optical cable shaft protective shell mold; Support mold of signal transmitting base station.  Part Details Part Material: ABS, PVC, PC, PP, BRASS, STAINLESS STEEL 304/316 Part Size: 255*176*100 mm Part Color: Any color Main Technology and Processes Mold Analysis → Sawing Machine Cutting → Depth Drill → CNC Rough Machining → Heat Treating → Finishing Machining → Wire Cutting → EDM → Polishing → Texture → Mold Assembly and Debugging → Mold Test Precautions for developing floor drain system.

Part Details Part Material: ABS, PVC, PC, PP, BRASS, STAINLESS STEEL 304/316 Part Size: 255*176*100 mm Part Color: Any color Main Technology and Processes Mold Analysis → Sawing Machine Cutting → Depth Drill → CNC Rough Machining → Heat Treating → Finishing Machining → Wire Cutting → EDM → Polishing → Texture → Mold Assembly and Debugging → Mold Test Precautions for developing floor drain system.

- The signal cover shall be made of acrylic high light transmittance material, which shall have the same effect as the lamp;

- We use the experience of rain shower mold for reference to improve the sound horn;

- In order to move the disassembly of the alarm, we use injection molding to wrap the strong magnet, and use the attraction of the magnet to fix the alarm;

- Shrinkage and deformation of plastic parts, warpage of stainless steel stamping parts, dimensional tolerance of circuit boards, and internal circuit planning of alarm products should be comprehensively considered.

Mold Details Project Leader: Ken Mold Type: Plastic injection mold, Stamping Die, Plastic Rubber Mould, Hot Chamber Die Casting, Foaming Mould, Press Tool Stamping Die Punch Die, Delivery time: 20-45 days Mold Material: NAK80, S136, 136H, 718H, P20, 718, 45#, etc.

Mold Details Project Leader: Ken Mold Type: Plastic injection mold, Stamping Die, Plastic Rubber Mould, Hot Chamber Die Casting, Foaming Mould, Press Tool Stamping Die Punch Die, Delivery time: 20-45 days Mold Material: NAK80, S136, 136H, 718H, P20, 718, 45#, etc.