-

-

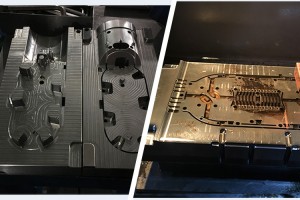

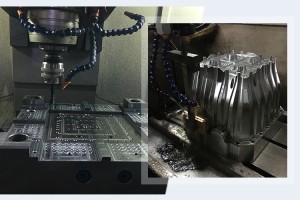

What about Multi Cavity Injection Moulds Making

Multi cavity mould is according to the size of the production capacity, product structure. It determines the appropriate number of cavities, more precision molds, processing difficulty. The higher the cost of the mold cavity. However, the unit cost of injection molded parts dropped significantly.

-

ABS extruded profile

ABS extrusion strip is widely used in building materials, door frame, decoration frame and photo frame. ABS extruded frame has good strength, toughness and corrosion resistance, and has good market competitiveness in price. In many years of research, development and test of our company, our self-produced ABS extruded frame is superior to its peers in the market in strength, toughness, corrosion resistance and aesthetics. It has made a great breakthrough in the European market and is widely used in European house decoration.

-

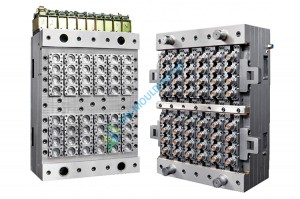

Professional Bottle Cap Mold

Uni-Moulding specializes in providing various types of bottle cap molds. We have complete R&D team, design department, high-precision processing equipment, quality inspection department and after-sales service team to ensure the excellent quality of each pair of molds. With 15 years of rich experience, we have made many kinds of caps, such as flip-top caps, bow-knot caps, five-gallon caps, cosmetic caps, etc. (up to 128 cavities). Our bottle cap molds have following advantages.

-

3D Print

With the development and maturity of 3D printing technology, 3D printing technology has been used many times in the product design and application of Uni-Molding. It is widely used in medical treatment, sports and building materials. Indoor golf courses, baseball delay devices, bedside decorations, industrial bearings, measuring containers, door and window handles, helmets, protective masks, etc.

However, 3D printing still has some technical limitations. -

Office Chair Back

Mold Base:DME

Mold Material: S136 Heat Treated

Part Material: TPU

-

Cable slack tray

Mould Base: DME

Mould Material: S136 Heat treated

Part Material: ABS

-

Dispenser Tray

This is a products used in the hospital for holding the waste of the wipers. From the mold to production and assembly all one in-house shop.

-

Pole Slack Box

Mold Base: DME Standard

Mold Material: S136 Heat Treated

Part Material: PP+GF

-

Pipe Fitting Mould

Mold Details:

Mold Base:DME Standard

Cavities & Cores: S136 Heat Treated

Cavities: 4 Impressions

-

Ground Box Mould

This box is applied underground. The most concern is the load strength for the part,but the cost is also to be addressed. We have to make the cost as lower as possible and meet the requirements.