Plastiki ABS e sa keneleng metsi Shower Pan Mold

Ena ke sehlahisoa sa moaho oa polasetiki se sebelisetsoang meaho ea drainage ea kamore ea ho hlapela le ho thibela metsi. Hobane matlo a 'marakeng oa Amerika Leboea kaofela ke mehaho ea foreimi ea lepolanka, hang ha kamore ea ho hlapela e se na metsi hantle, e tla tobana le hlobo, ho bola, mohloa le likotsi tse ling tse amanang le ntlo. Ka hona, nts'etsopele ea hlobo ea pan ea shaoara le ho etsoa ha pan ea polasetiki e sa keneleng metsi ho ka thusa batho ho rarolla mathata.

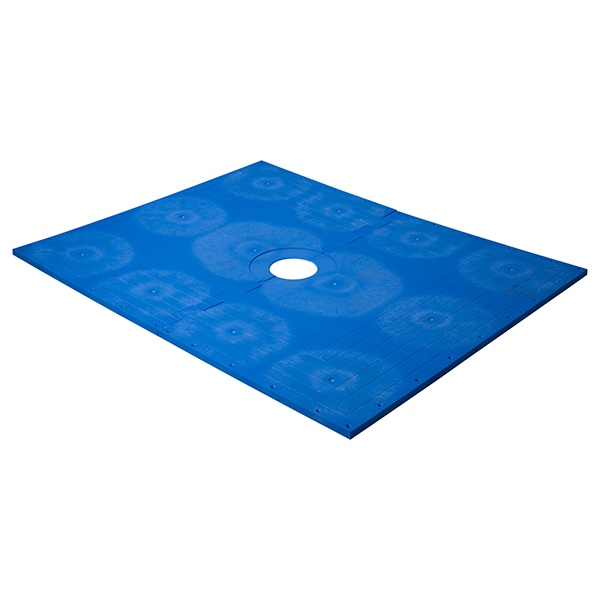

Lintlha tsa Karolo

Karolo ea Boitsebiso: ABS + 15% GF

Karolo ea boholo: 60 × 48 lisenthimithara

Karolo ea 'mala: Boputsoa kapa bohlooho

Boima ba 'mele: 17 KGS

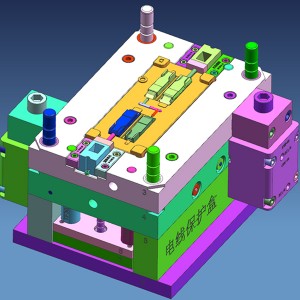

Theknoloji e ka Sehloohong le Mekhoa

Tlhahlobo ea Mold → Ho Seha Mochini oa Sawing → Ho Cheka Botebo → CNC Machining a Kgebellang → Phekolo ea Mocheso → Ho Qetella Mechini → Ho Seha Mohala → EDM → Ho benya → Sebopeho → Kopano ea Mold le ho Debugging → Tlhahlobo ea Mold

Mathata a Maholo le Litharollo

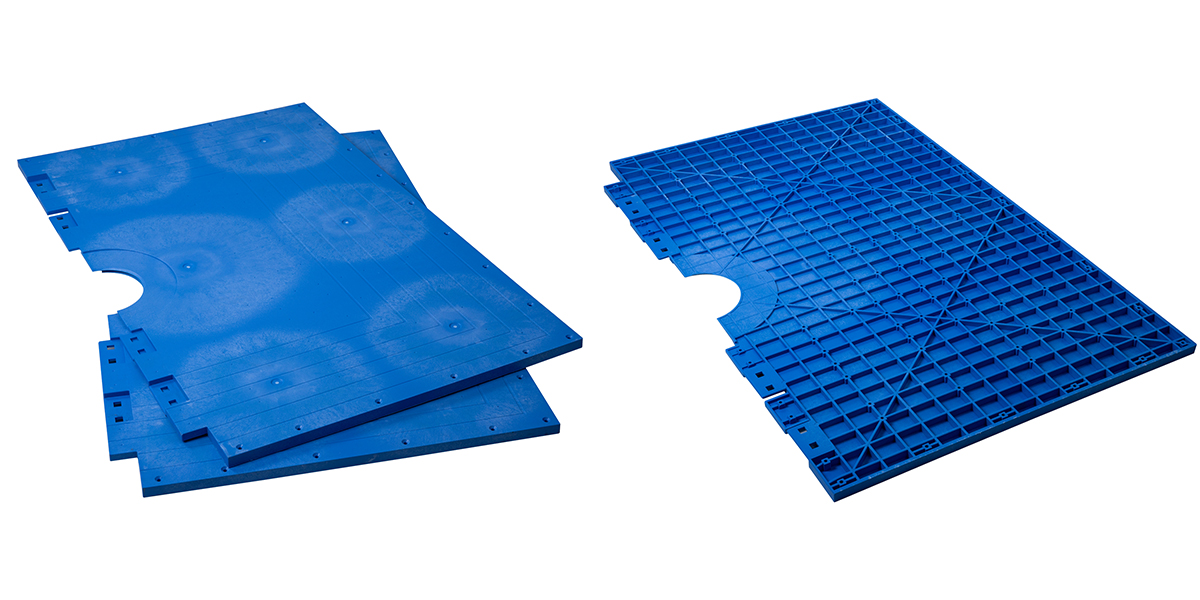

C1: Bakeng sa ho boloka litšenyehelo tsa lipalangoang, moreki o hloka hore boholo ba sehlahisoa bo laoloe ka har'a mefuta e itseng.

S1: Arola pane ea shaoara ka likarolo tse peli, eketsa sesebelisoa sa latch se ka bokelloang kaofela

C2: Rarolla bothata ba lithaele tse sa khomarelang.

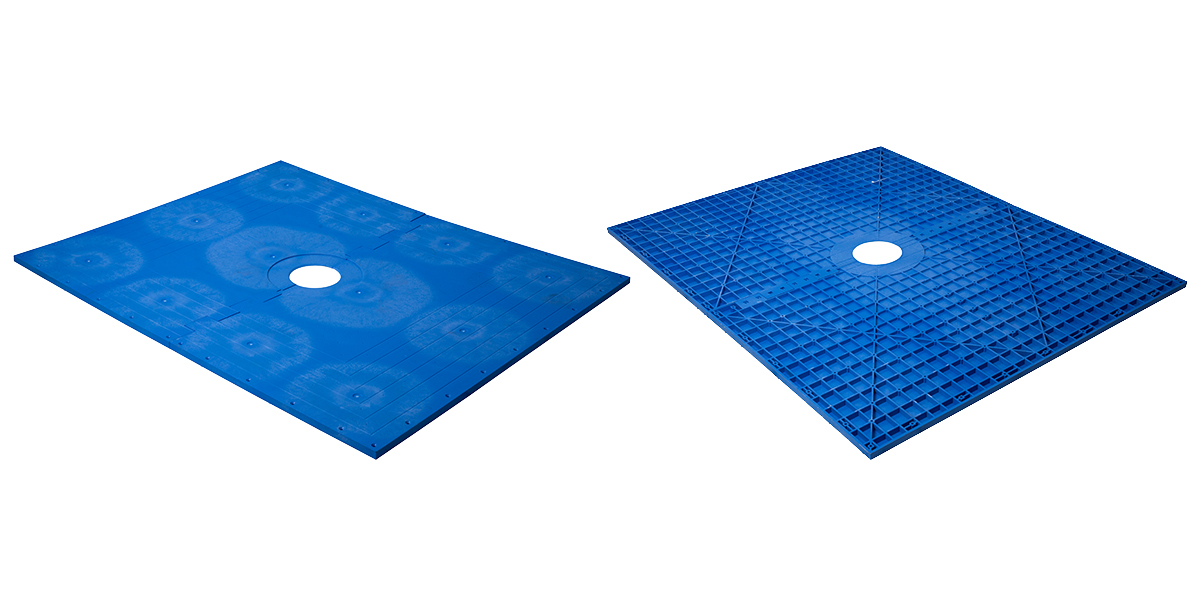

S2: Fetola bokaholimo ba hlobo ea pane ea shaoara ho tloha ho boreleli ho isa ho e mahoashe ka sebopeho.

C3: Deformation ea Pan ea Shower le warping.

S3: Ha e le hantle, lihlahisoa tsohle tsa polasetiki li na le mathata a deformation, shrinkage le warping. Ntlha ea pele, re ile ra eketsa palo le boholo ba heke. Ea bobeli, re ile ra eketsa boholo ba likanale tse pholileng. Ea boraro, re ile ra leka le ho sebelisa thepa e fetotsoeng e nepahetseng ka ho fetisisa.

C4: Mokhoa oa ho rarolla bothata ba matla a pan ea shaoara?

S4: Kenya fiber ea khalase hantle ka har'a lisebelisoa.

Lintlha tsa hlobo

Moetapele oa Morero: Zach

Mofuta oa hlobo: hlobo ea ente ea polasetiki ea ABS

Nako ea thomello: matsatsi a 35

Boitsebiso ba hlobo: P20, 718, 45 #, joalo-joalo.