-

Litšebeletso tsa Molding tsa Ente ea Silicone ea Metsi

Silika gel e sebelisoa haholo 'marakeng hobane ha e lokolle lintho tse chefo, e na le ho ama ha bonolo le ho phutholoha,' me e na le thepa e ntle ea 'mele le lik'hemik'hale mocheso o phahameng le mocheso o tlaase (-60c~+300c). Ho na le li-polymer tse ling tse 'maloa tse ka tšoanang le eona.

Elastomer e matla, e betere ho feta ho tiisa rabara, ho kenya motlakase hantle, le ho hanyetsa lik'hemik'hale, libeso, oli le metsi, thepa e ntle ea ho sebetsana le maemo a mabe.

Ka indasteri, joalo ka litiiso tsa oli, linotlolo tsa keyboard, lisebelisoa tsa ho kenya motlakase, likarolo tsa koloi, litlhoko tsa letsatsi le letsatsi joalo ka li-pacifiers, li-catheter tsa maiketsetso, li-respirators, liipone tsa lihoho, lieta tsa letlalo le liteki, lijana tsa lijo, jj.

Haeba u na le karolo efe kapa efe ea sliicone e hlokang ho hlahisoa, ikopanye le rona feela ho fumana boiphihlelo bo eketsehileng.

Phapano ke efe lipakeng tsa gel ea silica ea mokelikeli le gel e tiileng ea silica?

Silicone ea metsi

Liquid silica gel ke mofuta oa rabara ea silicone e nang le mocheso o phahameng oa mocheso. Ke gel ea metsi e nang le mokelikeli o motle, vulcanization e potlakileng, tšireletso e sireletsehileng le ea tikoloho, 'me e ka finyella litlhoko tsa boemo ba lijo ka ho feletseng.

Gel e tiileng ea silica

Solid silica gel ke mofuta oa lintho tse entsoeng ka polymer elastic, tse nang le litšobotsi tsa ho hanyetsa mocheso o phahameng, ho hanyetsa serame, ho hanyetsa solvent, ho hanyetsa ho khomarela, ho thibela ho khomarela, ho kenya motlakase, ho hanyetsa lik'hemik'hale 'me ho na le mefuta e mengata ea tšebeliso.

1. Gelisi ea silika ea mokelikeli le ponahalo e tiileng

(1) Joalokaha lebitso lena le bolela, gel ea silica e metsi e na le metsi 'me e na le metsi

(2) Gelisi e tiileng ea silica e tiile, ha e na metsi!

2. Tšebeliso ea gel ea silica ea metsi le gel e tiileng ea silica

(1) Gelisi ea silika e metsi hangata e sebelisoa lihlahisoa tsa bana, lihlahisoa tsa kichineng le lisebelisoa tsa bongaka, tse ka amang lijo le 'mele oa motho ka ho toba.

(2) Gelisi e tiileng ea silica e sebelisoa hangata litlhoko tsa letsatsi le letsatsi le likarolo tse fapaneng tsa indasteri le likarolo tsa koloi, joalo-joalo, mefuta ea ts'ebeliso e batla e pharaletse.

3. Tšireletseho ea gel e tiileng ea silica le gel ea silika ea metsi

(1) Liquid silica gel ke ponaletso e phahameng le lisebelisoa tsa boleng bo phahameng ba polokeho ea lijo, ho bopa ntle le ho eketsa moemeli oa vulcanizing le lisebelisoa tse ling tse thusang, ho bopeha ho tiisitsoeng.

(2) Gelisi e tiileng ea silica ke sesebelisoa sa tšireletso ea tikoloho e pepeneneng, ho theha litlhoko tsa ho eketsa sephekolo ho potlakisa nako ea ho folisa, le ho bopa ha hlobo e bulehileng.

4. Mokelikeli oa silika oa silika le mokhoa o tiileng oa ho bopa silika

(1) Silicone ea mokelikeli ke rabara ea silicone e entsoeng ka ente (LSR): lebitso le feletseng bakeng sa rabara e entsoeng ka ente ea silicone ea mokelikeli, lisebelisoa tsa ho phekola bakeng sa mochine oa ente.

Mochini oa ho etsa ente o na le ts'ebetso ea thekenoloji e bonolo haholo, ha ho hlokahale hore e be ts'ebetso ea lisebelisoa tsa sekhomaretsi se phahameng-thempereichara, ho kopanya, ho koala, thepa le ts'ebetso, ke a le mong feela oa basebetsi ba nkang lihlahisoa), lihlahisoa tse phahameng tse nepahetseng (ente e entsoeng ka pele ho tsohle. lenaneo la manual le nkeloe sebaka ke mochine oa A), lihlahisoa tse phahameng (A / B ho kopanya sekhomaretsi, tlas'a mocheso o itseng bakeng sa metsotsoana e seng mekae ho bōpeha), boloka, boloka motlakase, boloka thepa le tse ling tse ngata, li ka hlahisa sekhomaretsi sa mocheso o phahameng. lihlahisoa tsa tlhahiso! Ke nts'etsopele ea lisebelisoa tsa rabara tsa silicone lilemong tse 'maloa tse tlang.

(2) Mould o tiileng oa silica gel ke thepa e tala eo e leng sengoathoana se tiileng, ka mochini o kopanyang o kopanyang, mochini o sehang o khaoloa ka lihlahisoa ebe o etsa hlobo ea ente ka boholo bo nepahetseng le botenya, ebe o kena ka har'a hlobo, mochini o bopang khatello ka tlase. ho bopa ho itseng ha mocheso. Demoulding le lihlahisoa tsa polasetiki ka e tšoanang, hape lokela ho hloekisa hlobo.

5. Metsi a silica gel le lihlahisoa tse tiileng tsa silica gel mokhoa oa ho khetholla

Ponaletso ea gel ea silika ea metsi e phahame, ha e na monko, 'me sehlahisoa se na le molomo oa ente ea sekhomaretsi. Solid coarse pore silica gel e bonaletsang tlase, ntho e hlabang kapa monko o mong oa sekoaelo o monko o monate, sehlahisoa se se nang molomo oa ente.

-

Tee Joint & P-Trap Mold Ho Etsa le Tlhahiso ea Ente ea Mold

Tee le setsoe li sebelisoa haholo indastering ea liphaephe tsa metsi, liphaephe tsa moea le indasteri ea lisebelisoa tsa bongaka, E kenyelletsa libopeho tse fapaneng, boholo le meaho.

Bakeng sa tee e tloaelehileng ea tee, sebopeho se bonolo haholo, empa bakeng sa linaha le limmaraka tse fapaneng, boholo bo lumellanang le mekhoa ea ho fihlella li fapane.

Leha ho le joalo, ha ho nahanoa ka bothata ba ho khutla ha metsi le monko, mohaho o rarahaneng haholoanyane o phethoa motheong oa lihlopha tsa hlobo, tse ntseng li hloka phihlelo e lekaneng ea ho qapa le ho hlahisa.

Lilemong tse ka bang hlano tsa nts'etsopele, re akarelitse mefuta e fetang 80 ea boiphihlelo ba nts'etsopele ea hlobo ea lihlahisoa tsa tee le liphaephe.

Joalo ka peipi ea litšila ea Amerika ea ABS le PVC, e kenyelletsa ho etsoa ha liforomo tsa tee tsa ABS/PVC le ho bopeha ka ente ea boholo bo fapaneng joalo ka 1 inch, 1.5 inch, 2 inch, le 3 inch. Re boetse re na le boiphihlelo ba ho etsa mofuta oa mofuta oa PPR bakeng sa moreki oa rona oa Afrika Boroa(E le ho thusa bareki ho boloka litšenyehelo tsa nts'etsopele ea hlobo, ho latela lihlopha tse tharo tsa hlobo, re hlokometse tlhahiso ea likarolo tse 12 tsa tee ka ho nkela motheo oa hlobo le tse kentsoeng) . Ntho e thata ka ho fetisisa ke mokhoa oa ho etsa hlobo ea litsela tse tharo le tlhahiso ea lihlahisoa tsa lisebelisoa tsa bongaka tse nyenyane le mokhoa oa ho fafatsa o itekanetseng.

Lintlha tsa Karolo

Karolo ea lintho tse bonahalang: ABS, PVC, PPR, PP, PC

Karolo ea 'mala: 'Mala ofe kapa ofe

Theknoloji e ka Sehloohong le Mekhoa

Tlhahlobo ea Mold → Ho Seha Mochini oa Sawing → Ho Cheka Botebo → CNC Machining a Kgebellang → Phekolo ea Mocheso → Ho Qetella Mechini → Ho Seha Mohala → EDM → Ho benya → Sebopeho → Kopano ea Mold le ho Debugging → Tlhahlobo ea Mold

Boiphihlelo bo ka sehloohong ba Mold Development

P Trap Mold, Tee PVC Fitting Connector(1/2”, 3/4”, 1”, 1-1/4”, 1-1/2”, 2”, 3”) , 2 in. Glueless Soundproof DWV Sanitary Tee, 2 in. DWV PVC P-Trap with Solvent Weld Joint, 2″ Plain 90 Degree PVC Tee

Lintlha tsa hlobo

Moetapele oa Morero: Zach

Mofuta oa hlobo: hlobo ea ente ea polasetiki

Nako ea ho fana: matsatsi a 20-45

Boitsebiso ba hlobo: NAK80, S136, 136H, 718H, P20, 718, 45 #, joalo-joalo.

-

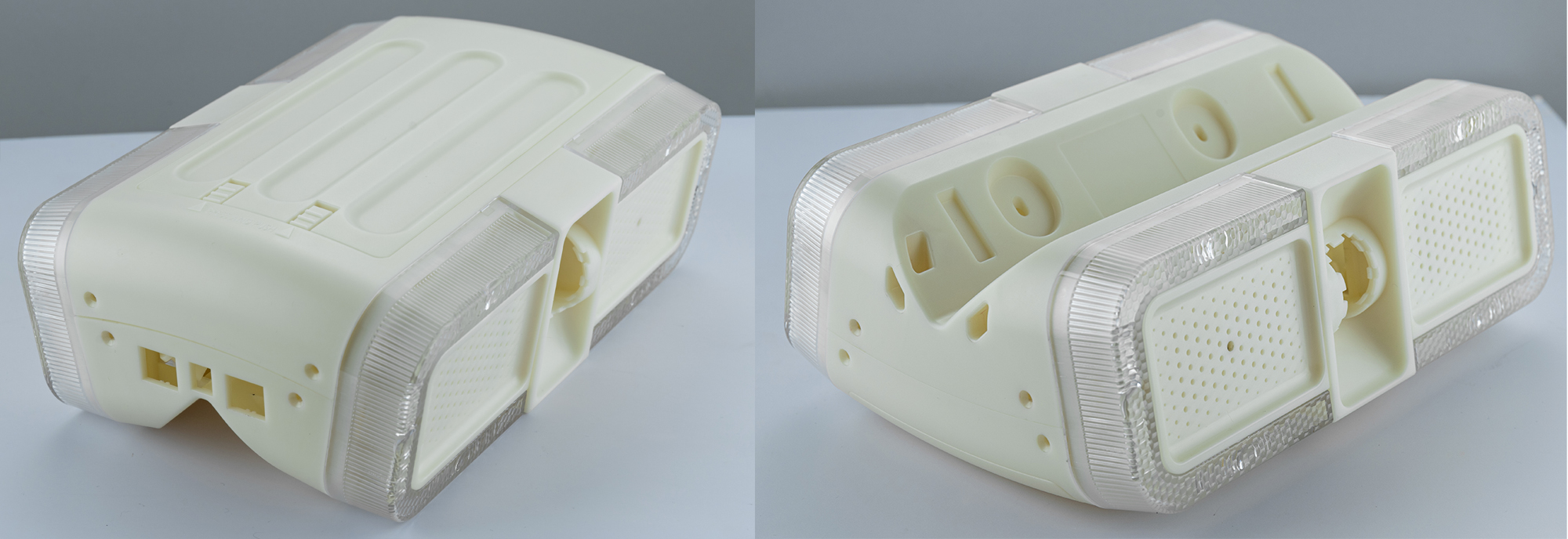

Ntlafatso ea Mould Case ea Battery le Litšebeletso tsa Mould Molding tsa ABS Battery Shell

Betri e re behetse e sebelisoang haholo indastering ea likoloi le lithuthuthu, E kenyelletsa mefuta e mengata e fapaneng le litekanyo.

Nakong ea lilemo tse 9, Uni Molding e thehile hlobo e fetang 50 ea ente ea betri le likarolo tse fapaneng tsa likarolo tsa betri. Boemong ba betri, nts'etsopele ea hlobo e amana haholo le hlobo ea ente ea semathi se chesang ea sekoaelo sa betri, hlobo e kaholimo ea sekoaelo sa betri, le hlobo e hatakelang ea likarolo tsa koporo.

Ts'ebetsong ea ts'ebelisano e tsoelang pele ea tlhahiso, re lula re ithuta ka molao-motheo oa ho sebetsa oa betri le litemoso tsa kopano ea boto ea potoloho. Ntle le ho rarolla bothata ba nts'etsopele ea hlobo ea khetla ea betri, e ka thusa hape ho kopanya le ho etsa liteko tsa betri.

Lintlha tsa Karolo

Karolo ea Boitsebiso: ABS, Brass

Litekanyo tse ka hare: 106 × 63 × 61 limilimithara; 143 × 79.5 × 73.5 limilimithara; 145 × 64 × 111 limilimithara; 144 × 80 × 110 limilimithara; 107×68×82 limilimithara; 105 × 52 × 68 limilimithara; 105×26×69 limilimithara; 105×68×108 limilimithara;

Karolo ea 'mala: 'Mala ofe kapa ofe

Theknoloji e ka Sehloohong le MekhoaTlhahlobo ea Mold → Ho Seha Mochini oa Sawing → Ho Cheka Botebo → CNC Machining a Kgebellang → Phekolo ea Mocheso → Ho Qetella Mechini → Ho Seha Mohala → EDM → Ho benya → Sebopeho → Kopano ea Mold le ho Debugging → Tlhahlobo ea Mold

Litaelo tsa ho theha sistimi ea drainage ea fatše.

Ha ho etsoa ente ea hlobo ea betri, bothata ba ho fokotseha ha bokaholimo ba sehlahisoa le ho hokahanya bo rarolloa haholo;

Sebelisa ABS e thibelang malakabe ho nkela ABS e tloaelehileng bakeng sa ho bopa ente;

Motlakase oa setempe oa koporo o entsoe ka chrome ebe o ABS holim'a ente e entsoeng, e rarollang bothata ba ho tiisa betri hantle.

Lintlha tsa hlobo

Moetapele oa Morero: Zach

Mofuta oa Mould: hlobo ea ente ea polasetiki, Stamping Die, Mould Rabara ea Plastiki, Mohaho o chesang oa Chamber Die Casting, Foaming Mould, Tobetsa Tool Stamping Die Punch Die,

Nako ea ho fana: matsatsi a 20-45

Boitsebiso ba hlobo: NAK80, S136, 136H, 718H, P20, 718, 45 #, joalo-joalo.

-

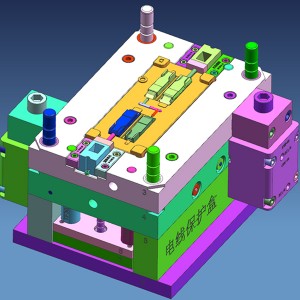

Sistimi ea alamo ea polokelo e bohlale ea Mold Development

UNI MOLDING e na le boiphihlelo ba lilemo tse 15 ho nts'etsopele ea hlobo ea ente ea polasetiki, haholo-holo ka har'a hlobo ea khetla ea lisebelisoa tsa elektroniki, hlobo ea ts'ehetso, mochini oa mochini oa polasetiki. Ts'ebetsong ea nts'etsopele e tsoelang pele, bareki ba bangata ba 'nile ba ntlafatsa lihlahisoa tsa bona, ho tloha ho tšepe ea tšepe ho ea ho ts'ebetso ea tšepe e sa hloekang, ho tloha ts'ebetsong ea tšepe ho ea ho ente ea polasetiki. Re lula re ntlafatsa mathata a amanang le ho hanyetsa kutu, ho hanyetsa mocheso o phahameng le ho hanyetsa UV ea ho bopa ente ea polasetiki ho etsa hore ts'ebetso ea lihlahisoa tsa polasetiki e be betere ho feta lihlahisoa tse ling tsa ts'ebetso. Ka tsoelo-pele e potlakileng lilemong tsa morao tjena, re thehile hlobo ea polasetiki ea optical fiber winding box; Bottom line optical thapo shaft sireletsang khetla hlobo; Ts'ehetso ea hlobo ea setsi sa setsi sa ho fetisa matšoao.

Lintlha tsa KaroloKarolo ea Boitsebiso: ABS, PVC, PC, PP, BRASS, STAINLESS STEEL 304/316 Karolo ea Boholo: 255 * 176 * 100 mm Karolo ea Mobala: 'Mala ofe kapa ofeTheknoloji e ka Sehloohong le MekhoaTlhahlobo ea Mold → Ho Seha Mochini oa Sawing → Ho Cheka Botebo → CNC Machining a Kgebellang → Phekolo ea Mocheso → Ho Qetella Mechini → Ho Seha Mohala → EDM → Ho benya → Sebopeho → Kopano ea Mold le ho Debugging → Tlhahlobo ea MoldLitaelo tsa ho theha sistimi ea drainage ea fatše.

Lintlha tsa KaroloKarolo ea Boitsebiso: ABS, PVC, PC, PP, BRASS, STAINLESS STEEL 304/316 Karolo ea Boholo: 255 * 176 * 100 mm Karolo ea Mobala: 'Mala ofe kapa ofeTheknoloji e ka Sehloohong le MekhoaTlhahlobo ea Mold → Ho Seha Mochini oa Sawing → Ho Cheka Botebo → CNC Machining a Kgebellang → Phekolo ea Mocheso → Ho Qetella Mechini → Ho Seha Mohala → EDM → Ho benya → Sebopeho → Kopano ea Mold le ho Debugging → Tlhahlobo ea MoldLitaelo tsa ho theha sistimi ea drainage ea fatše.- Sekoahelo sa pontšo se tla etsoa ka lisebelisoa tsa acrylic high light transmittance, tse tla ba le phello e tšoanang le ea lebone;

- Re sebelisa phihlelo ea hlobo ea pula ea pula bakeng sa ho bua ka ho ntlafatsa lenaka la molumo;

- E le hore re tsamaise disassembly ea alamo, re sebelisa ente molding ho thatela makenete e matla, 'me re sebelise ho hohela ha makenete ho lokisa alamo;

- Shrinkage le deformation ea likarolo tsa polasetiki, warpage ea likaroloana tsa tšepe tse sa hloekang, mamello e lekaneng ea liboto tsa potoloho, le moralo oa ka hare oa potoloho ea lihlahisoa tsa alamo li lokela ho nkoa ka ho pharaletseng.

Lintlha tsa hloboMoetapele oa Morero: Mofuta oa Ken Mold: hlobo ea ente ea polasetiki, Stamping Die, Mould Rabara ea Plastiki, Mould ea Chelete ea Chamber Die Casting, Foaming Mould, Press Tool Stamping Die Punch Die, Nako ea ho fana: matsatsi a 20-45 Mold Material: NAK80, S136, 136H, 718H , P20, 718, 45#, joalo-joalo.

Lintlha tsa hloboMoetapele oa Morero: Mofuta oa Ken Mold: hlobo ea ente ea polasetiki, Stamping Die, Mould Rabara ea Plastiki, Mould ea Chelete ea Chamber Die Casting, Foaming Mould, Press Tool Stamping Die Punch Die, Nako ea ho fana: matsatsi a 20-45 Mold Material: NAK80, S136, 136H, 718H , P20, 718, 45#, joalo-joalo. -

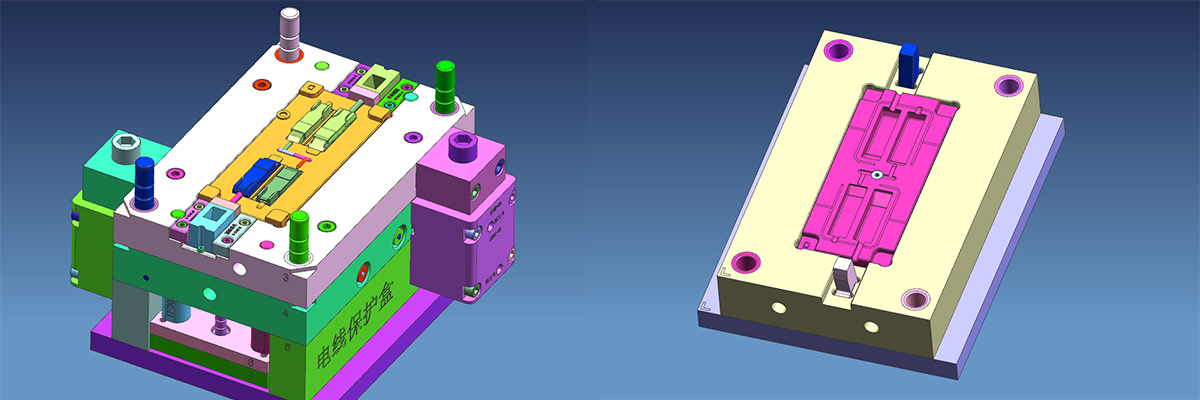

Moetsi oa Mould oa Ente ea Plastiki le Tšebeletso ea Mold ea Ente bakeng sa Maraka oa USA bakeng sa Sekoaelo sa Cable ea Plastiki

Uni Molding e entse lihlopha tse fetang 30 tsa mefuta e fapaneng ea li-junction box mold, ho kenyeletsoa letoto la liforomo tsa polasetiki tse amanang le optoelectronic, joalo ka hlobo e nang le matla a phahameng a motlakase, mochini oa optical fiber junction box, hlobo ea meter shell, hlobo ea tšireletso ea terata, jj. . re na le liphihlelo tse ngata tsa tlhahiso ea hlobo ea li-junction box.

Le hoja sekoahelo sa cable morerong ona se le senyenyane, lintlha tse ngata li lokela ho nkoa. Hobane sena ke sehlahisoa se sebelisoang hape ka makhetlo a mangata, ho phaella ho ho thibela botsofali, ho thibela botsofali, ho hanyetsa UV, ho thibela metsi le lintho tse ling tse amanang le tsona, ho feto-fetoha ha eona ho sebelisoa hape ho lokela ho nkoa.

Lintlha tsa Karolo

Karolo ea Boitsebiso: PP + UV

Karolo ea 'mala: Botšo

Boima ba karolo: 8g

Theknoloji e ka Sehloohong le Mekhoa

Tlhahlobo ea Mold → Ho Seha Mochini oa Sawing → Ho Cheka Botebo → CNC Machining a Kgebellang → Phekolo ea Mocheso → Ho Qetella Mechini → Ho Seha Mohala → EDM → Ho benya → Sebopeho → Kopano ea Mold le ho Debugging → Tlhahlobo ea Mold

Mathata a Maholo le Litharollo

C1: Ho tsofala ha sehlahisoa sa polasetiki;

S1: Etsa karolo ea 'mala hore e be botšo bo lefifi 'me u kenye UV, e ka thibelang botsofali le UV ka katleho.

C2: Netefatsa hore karolo e hloka ho menwa kgafetsa ntle le ho robeha le ho fetoha tshweu;

S2: Sebelisa no-silicon copolymerized PP e le thepa ea motheo, 'me u kenye lisebelisoa tse ling tse thusang ka mokhoa o nepahetseng ho finyella phello e ntle ka ho fetisisa ea PP (Ts'ebetso e ntle ka ho fetisisa, matla a phahameng, ho tiea ho phahameng, ho hanyetsa mocheso o motle, botsitso bo botle ba boemo bo tlaase, ho tiea ha mocheso o tlaase. (ho tenyetseha hantle), pepeneneng e ntle, le ho benya ho hotle.)

Lintlha tsa hlobo

l Moetapele oa Morero: Zach

l Mofuta oa hlobo: hlobo ea ente ea polasetiki ea PP

l Nako ea ho fana: matsatsi a 28

l Boholo ba Sehlahisoa: 10 * 6 * 3

l Boholo ba hlobo: 400x280x360 limilimithara

l Mould Cavity: 2 likoti

l Lintho tse ka Sehloohong tsa Mold: S136

l Boitsebiso ba hlobo: 718H, P20, 718, 45 #, joalo-joalo.

l Sistimi ea Ente ea Mold: Heke ea lintlha

l Nako ea Potoloho ea Mold: 12”

-

Plastic Ente Shower Drain Mold Stamping Die Casting Mold

UNI MOLDING e hatetse pele ka ho etsa liforomo tsa boleng bo holimo tsa shaoara mme haholoholo theknoloji e phahameng ea ho stamping hlobo, hlobo ea ho lahla, hlobo ea ente ea polasetiki e nang le tharollo ea ho bopa ho feta. UNI MOLDING e hatetse pele ka ho etsa liforomo tsa boleng bo holimo tsa shaoara mme haholoholo theknoloji e phahameng ea ho stamping hlobo, hlobo ea ho lahla, hlobo ea ente ea polasetiki e nang le tharollo ea ho bopa ho feta.

Re boetse re fana ka tharollo e entsoeng ka tloaelo bakeng sa R&D le moralo oa mokatong oa shaoara ea polasetiki le nts'etsopele ea mohlala o mocha o nang le tafole le drain ka sete e felletseng, ho khothaletsa moralo oa bonono joalo-joalo. Ka hona, UNI MOLDING e tumme ka thekenoloji ea rona ea R&D ho mochini oa mochini oa shaoara le ntlafatso ea rona ea mohlala oa polasetiki.

Lintlha tsa Karolo

Karolo ea lintho tse bonahalang: ABS, PVC, PC, PP, BRASS, STINLESS STEEL 304/316, BRASS, ZINK, ALUMINIUM

Karolo ea boholo: lisenthimithara tse 3,5, lisenthimithara tse 4, drainage ea lisenthimithara tse 6; 6/12/24/28/30/32/36/48 inches linear drain

Karolo ea 'mala: 'Mala ofe kapa ofe

Theknoloji e ka Sehloohong le Mekhoa

Tlhahlobo ea Mold → Ho Seha Mochini oa Sawing → Ho Cheka Botebo → CNC Machining a Kgebellang → Phekolo ea Mocheso → Ho Qetella Mechini → Ho Seha Mohala → EDM → Ho benya → Sebopeho → Kopano ea Mold le ho Debugging → Tlhahlobo ea Mold

Stamping Die, Casting Mold, Plastic Rubber Mould, Hot Chamber Die Casting, Sand Mold Casting, Compress Molding, Foaming Mould, Press Tool Stamping Die Punch Die

Litaelo tsa ho theha sistimi ea drainage ea fatše.

- Rala moepa o itseng ho nolofatsa drainage;

- Litekanyo le thepa ea liphaephe tsa drainage linaheng le libakeng tse fapaneng li lokela ho nkoa;

- Thibela tšepe e sa hloekang 304 hore e se ke ea oa;

- Ho lokisoa ha angle ea bophahamo nakong ea ho kenya;

- Setifikeiti se felletseng sa thepa le lisebelisoa tse tšoanelehang ho netefatsa setifikeiti se loketseng;

Lintlha tsa hlobo

Moetapele oa Morero: Zach

Mofuta oa hlobo: hlobo ea ente ea polasetiki, Stamping Die, Casting Mold, Plastic Rubber Mould, Hot Chamber Die Casting, Sand Mold Casting, Compression Molding, Foaming Mould, Press Tool Stamping Die Punch Die,

Nako ea ho fana: matsatsi a 20-45

Boitsebiso ba hlobo: NAK80, S136, 136H, 718H, P20, 718, 45 #, joalo-joalo.

-

Plastiki ABS e sa keneleng metsi Shower Pan Mold

Ena ke sehlahisoa sa moaho oa polasetiki se sebelisetsoang meaho ea drainage ea kamore ea ho hlapela le ho thibela metsi. Hobane matlo a 'marakeng oa Amerika Leboea kaofela ke mehaho ea foreimi ea lepolanka, hang ha kamore ea ho hlapela e se na metsi hantle, e tla tobana le hlobo, ho bola, mohloa le likotsi tse ling tse amanang le ntlo. Ka hona, nts'etsopele ea hlobo ea pan ea shaoara le ho etsoa ha pan ea polasetiki e sa keneleng metsi ho ka thusa batho ho rarolla mathata. Lintlha tsa Karolo Karolo ea Boitsebiso: ABS + 15% GF Karolo ea Boholo: 60 × 48 inch... -

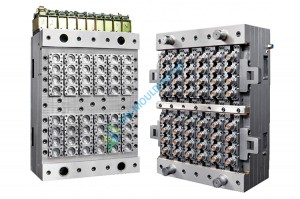

Ho thoe'ng ka Multi Cavity Injection Molds Molds Ho etsa

Multi cavity hlobo ke ho ea ka boholo ba bokhoni ba tlhahiso, sebopeho sa sehlahisoa. E khetholla palo e nepahetseng ea li-cavities, hlobo e nepahetseng haholoanyane, bothata ba ho sebetsa. Litsenyehelo tse phahameng tsa mokoti oa hlobo. Leha ho le joalo, theko ea yuniti ea likarolo tse entsoeng ka ente e theohile haholo.

-

Boemo ba ABS bo fetelletseng

ABS extrusion strip e sebelisoa haholo ho thepa ea moaho, foreimi ea mamati, foreimi ea mokhabiso le foreimi ea lifoto. ABS extruded frame e na le matla a matle, ho tiea le ho hanyetsa kutu, hape e na le tlholisano e ntle ea 'maraka ka theko. Lilemong tse ngata tsa lipatlisiso, nts'etsopele le liteko tsa k'hamphani ea rona, foreimi ea rona e iketselitseng ea ABS e phahametse lithaka tsa eona 'marakeng ka matla, ho tiea, ho hanyetsa kutu le botle bo botle. E entse katleho e kholo 'marakeng oa Europe' me e sebelisoa haholo ho khabisa ntlo ea Europe.

-

Professional Bottle Cap Mold

Uni-Moulding e ipabola ka ho fana ka mefuta e fapaneng ea hlobo ea botlolo. Re na le sehlopha se felletseng sa R&D, lefapha la meralo, lisebelisoa tse sebetsang hantle haholo, lefapha la tlhahlobo ea boleng le sehlopha sa litšebeletso tsa kamora thekiso ho netefatsa boleng bo botle ba para e 'ngoe le e 'ngoe ea hlobo. Ka lilemo tse 15 tsa phihlelo e ruileng, re entse mefuta e mengata ea li-caps, tse kang li-flip-top caps, li-bow-knot caps, li-gallon tse hlano, li-cosmetic caps, joalo-joalo (ho fihlela ho 128 cavities). Mefuta ea rona ea botlolo ea botlolo e na le melemo e latelang.

-

3D Print

Ka nts'etsopele le kholo ea theknoloji ea khatiso ea 3D, theknoloji ea khatiso ea 3D e 'nile ea sebelisoa ka makhetlo a mangata moralong oa sehlahisoa le ts'ebelisong ea Uni-Molding. E sebelisoa haholo kalafo ea meriana, lipapali le thepa ea mohaho. Libaka tsa kolofo tsa kahare, lisebelisoa tsa ho lieha ha baseball, mekhabiso e pel'a bethe, li-bearings tsa indasteri, lijana tsa ho lekanya, mabati le lifensetere, lihelmete, limaske tse sireletsang, jj.

Leha ho le joalo, khatiso ea 3D e ntse e na le mefokolo ea tekheniki. -

Setulo sa Ofisi Khutla

Mold Base:DME

Mold Material: S136 Mocheso o Phekotsoe

Karolo ea lintho tse bonahalang: TPU