Super Purchasing for Small Injection Molding - Cable slack tray – Uni-Moulding

Super Purchasing for Small Injection Molding - Cable slack tray – Uni-Moulding Detail:

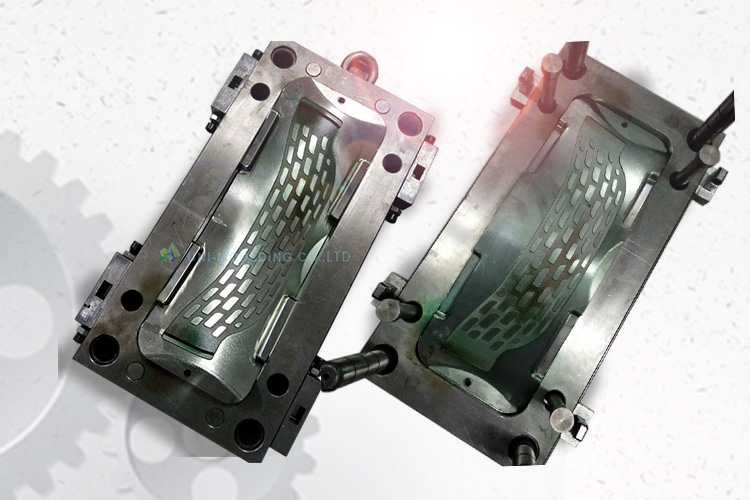

Ground Box Mould

Export Country:

India

Completion Time:

1 Month

Tag: Injection Mould

Challange

There are many angle lifters applied for the mould and space for some of the lifters were very tight. But the customer has to get the features as required.

Solutions

Have the mechanism changed for these features.

Product Application Field

Industrial communication cable tray

Main Challenges

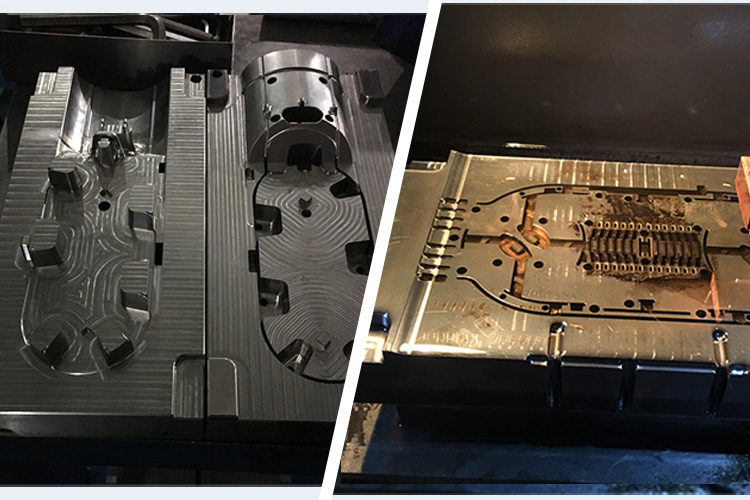

The position of the winding reel in the middle of the product has a thin wall thickness and is very dense. EDM processing is very complex, and the mold is very easy to break. There are many defective products and serious material shortage in injection molding. For the wall thickness problem, first, we replaced the product material and used PC + ABS material, which increases the willfulness of the product and is not easy to break; Second mold core material is treated with S136 heat treatment to increase the life of strength die. Second, we make the middle part into replacement inserts, which can not only solve the problems of mold damage and repair caused by improper injection molding operation, but also solve the problem of gas trapping and material shortage of products.

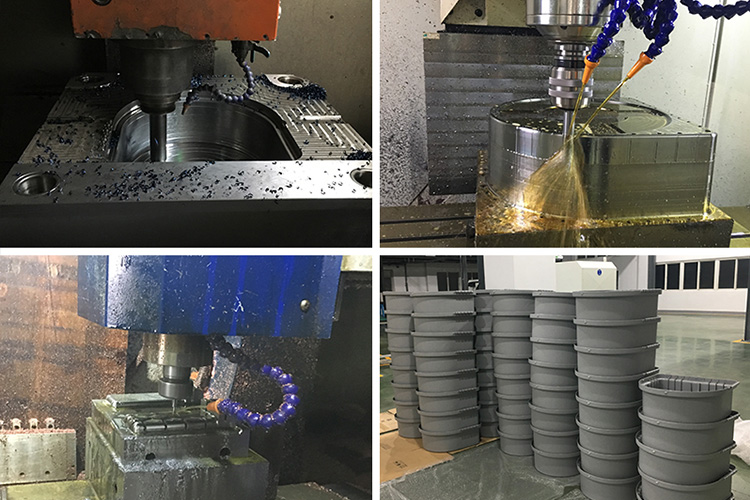

Main Technology

Mold Analysis, CNC Rough Machining, Heat Treating, Finishing Machining, Wire Cutting, EDM, Polishing, Texture.

Mold Details:

Maximum die size: 1100*1000*800mm

Export Area: EU

Delivery time: 45 days

Part Quantity: 5 pcs

Mold Quantity: 4 sets

Number of Processed Sliders: 6 pcs

Mold Material: 718H, NAK80, P20, 718, 45#, etc.

Part Material: PC+ABS

Project Leader: Ken Yeo

Key Words

PC+ABS, Air Trap, Shrinkage, Distortion

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" may be the persistent conception of our organization for that long-term to establish jointly with customers for mutual reciprocity and mutual gain for Super Purchasing for Small Injection Molding - Cable slack tray – Uni-Moulding , The product will supply to all over the world, such as: South Korea , Tunisia , Tunisia , Insisting on the high quality generation line management and customers expert assistance, we now have designed our resolution to offer our buyers using the to start with amount getting and just after services practical experience. Maintaining the prevailing friendly relations with our buyers, we however innovate our solution lists all of the time to satisfy the brand new demands and adhere to the most up-to-date development of the market in Malta. We are ready to face the worries and make the improve to understand all the possibilities in international trade.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!